Finding and fixing HRSG tube leaks before they can grow to the point of requiring an unplanned outage to correct them is a priority of many maintenance managers during annual inspections. Tube-to-header welds are particularly susceptible to cracking and leakage given today’s fast-start/fast-ramp operating practices.

There are several tools inspection personnel traditionally have used to inspect these welds for cracks—including visual, dye-penetrant, magnetic particle, and x-ray. One or more of them may require special certifications, surface preparation prior to use, and/or more working room than is available.

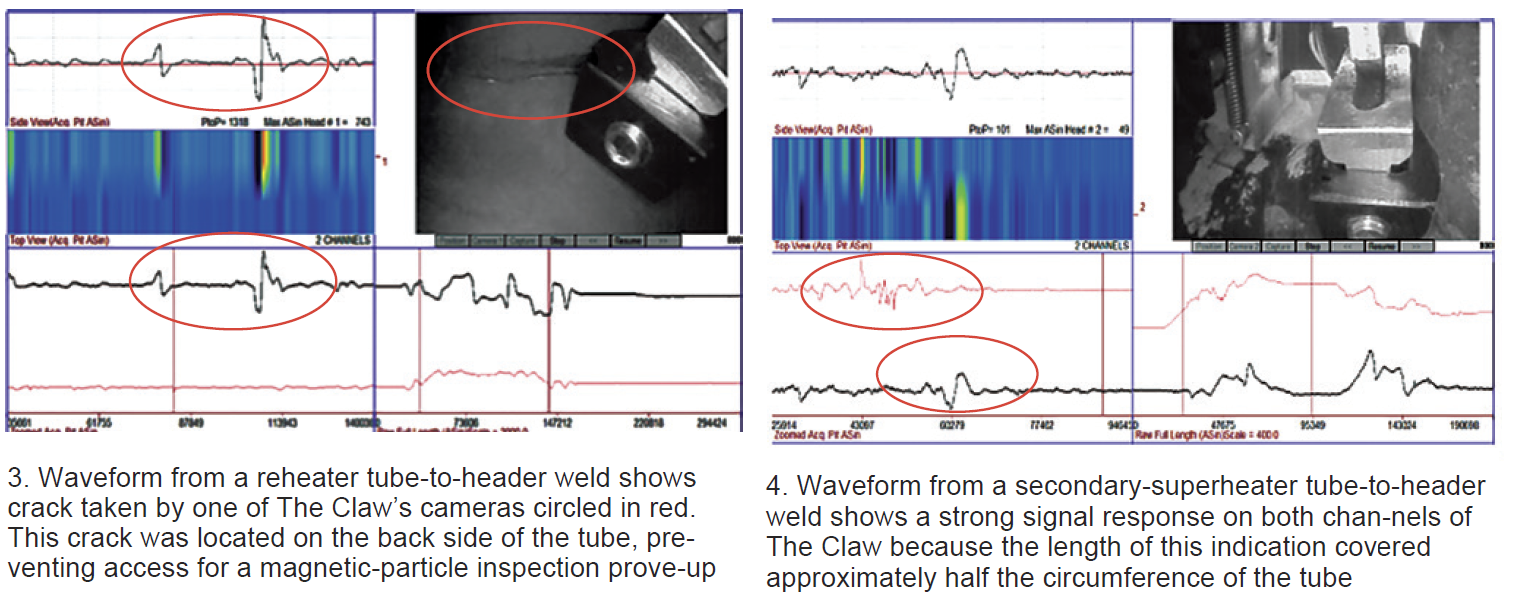

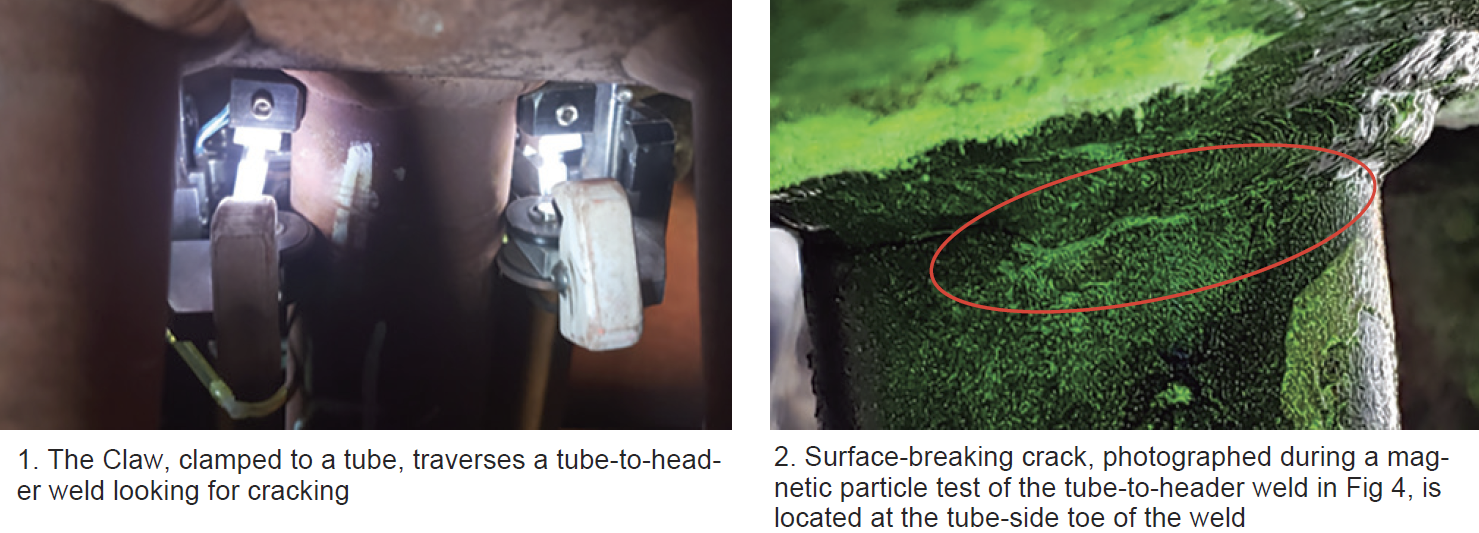

A relatively new tool for inspecting tube-to-header welds, “The Claw,” developed by TesTex Inc, Pittsburgh, uses the Balanced Field Electromagnetic Technique (BFET) to detect cracking on the surface, and below it to depths of 0.250 in. (Figs 1 and 2). It was on display for viewing by owner/operators of heat-recovery steam generators at the 2019 meeting of the HRSG Forum with Bob Anderson.

Over the last couple of years, TesTex technicians have gained a great deal of experience with The Claw and are now able to examine up to about 200 tube-to-header welds in one shift. Fig 1 shows the BFET’s two sensors spaced 180-deg apart and companion cameras traversing the full circumference of the weld. Important: No surface preparation is needed to perform the BFET inspection in HRSGs (Figs 3 and 4).