When you’re sick, or something seems “off,” what do you do? Many people search the web, often arriving at a WebMD, Mayo, or equivalent site, for some initial information. If symptoms persist, you go to your primary-care physician. The doc may tell you to see a specialist or even a surgeon.

Thankfully, when your steam turbine seems “off,” and you suspect the rotor, you can get “integrated care” from the 500 folks at MD&A, including 200 seasonal traveling turbine experts. Who says doctors don’t make house calls?

Think of the “Bowed Rotor to Straight Rotor” presentation by Rob Kilroy in MD&A’s Spring 2021 Webinar Series, summarized here, as WebMD. If the turbine rotor needs an official diagnosis, MD&A will send inspection specialists to your site. If the diagnosis suggests repairs, the company will handle those as well.

If you are recording a gradual increase in rotor vibration over a long period, it may be time to listen up. The rotor may be bowed, caused by persistent asymmetrical heating or cooling of the shaft. Pre-1960s turbines rarely experienced bowing. Today’s longer, more slender rotors with a reduced number of bearing pedestals and more aggressive operating parameters are more susceptible.

The MD&A crew is seeing around a dozen bowed rotors each year. That may not seem like a lot, but given the damage a bowed rotor can do, it’s best not to find out the hard way.

In the webinar, Kilroy explains rotor bowing is defined by the total indicated reading (TIR). If the TIR is less than 0.03 in., the bowing is minor, if between 0.04 and 0.015 in., it’s moderate, and above 0.016 in., consider it severe. Severely bowed rotors typically cannot be balanced, and will require an engineered straightening solution.

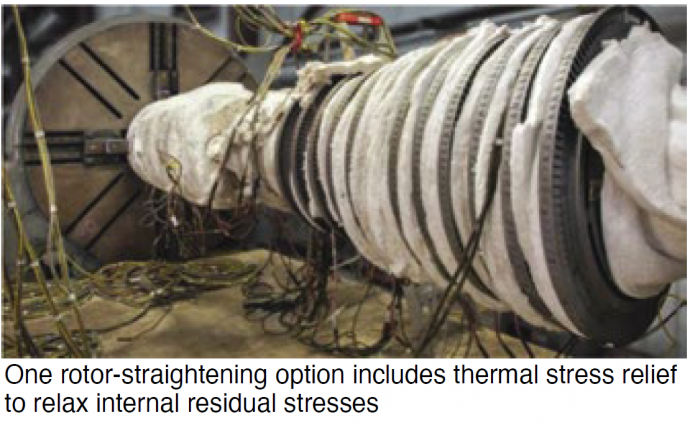

The turbine/generator repairs engineer delineates three categories of straightening options, once the detailed in-casing and disassembly inspections are completed: Machining/throwing of journals, stress relief/heat lathe, and thermal straightening (photo). The last two typically do not require resizing of the bearings.

Best of all, Kilroy reviews seven case studies, the first three on the cusp of severe with max TIRs of 0.015. In general, the “surgeries” MD&A performed return the rotors to a TIR of between 0.001 and 0.005. In one case, a rotor with “all kinds of problems” and a 0.007-in. TIR at the turbine end and 0.053 at the generator end, MD&A’s solution reduced the TIRs to 0.001 in. at both ends.

Rotors from a variety of manufacturers are featured in the case studies. Frequently, the rotor was subjected to multiple straightening options and ancillary machining and component replacements. You’ll understand the innovative thinking that’s required once you watch the video (users only).