So you switch hemispheres in both directions, west to east then north to south, and you discover that the pesky HRSG operational issues and concerns you are familiar with are much the same everywhere.

So you switch hemispheres in both directions, west to east then north to south, and you discover that the pesky HRSG operational issues and concerns you are familiar with are much the same everywhere.

The 2018 Australasian Boiler and HRSG Users Group (ABHUG) Conference and Workshops, held last November, confirmed this view. The organization’s 11th annual conference in Brisbane, Queensland, chaired by Barry Dooley of Structural Integrity Associates Inc, provided an interactive forum for new information and technology specific to HRSG challenges in combined-cycle plants. There were in-depth case studies on plant issues and possible solutions, and pointed discussions among equipment users, suppliers, and international industry experts.

The more universal interactions focused on:

-

- Cycle chemistry, instrumentation, and flow-accelerated corrosion.

- HRSG thermal transients.

- Oxide growth and exfoliation.

- Attemperators, condensate return, superheater (SH)/reheater (RH) drain management.

- Steam-turbine bypass operations.

- Experience and research into the evolving field of film-forming substances.

- Awareness and detection of air in-leakage.

- Activities of the International Association for the Properties of Water and Steam—in particular the organization’s Technical Guidance Documents (TGD) of great value to powerplant owners and operators, which can be downloaded online at no cost.

Highlights of the meeting are summarized below.

Steam-drum cracking. Presentations included several case histories of HRSG steam-drum cracking, occurring primarily at drum-to-downcomer and circumferential welds. Inspection methods included visual, phased array, magnetic particle, ultrasonic, replication, and hardness.

Poor control of rolling and heat treatment of the original materials were highlighted as culprits, followed by weldability concerns. A summary point on weldability: Parent-material properties are dependent on manufacturing parameters for high-strength low-alloy (HSLA) steels, and welding introduces heat that disrupts the parent-material microstructures. Proper microstructures cannot be regenerated by post-weld heat treatment. Repairs, when required, can be problematic.

The common root cause was summarized as reheat cracking propagated by corrosion fatigue. The use of HSLA steels (for reduced wall thickness and increased allowable stress) contributes to this problem because of a unit’s higher operating stresses and material susceptibility to reheat cracking.

Fitness-for-service issues were reviewed that consider stresses caused by pressure, the simple weight of water and steam, and thermal effects of startup and shut down.

Reheater tube failures were examined for a 760-MW 2 × 1 combined cycle commissioned in 2002. The subject three-pressure, three-module HRSG does not have duct burners.

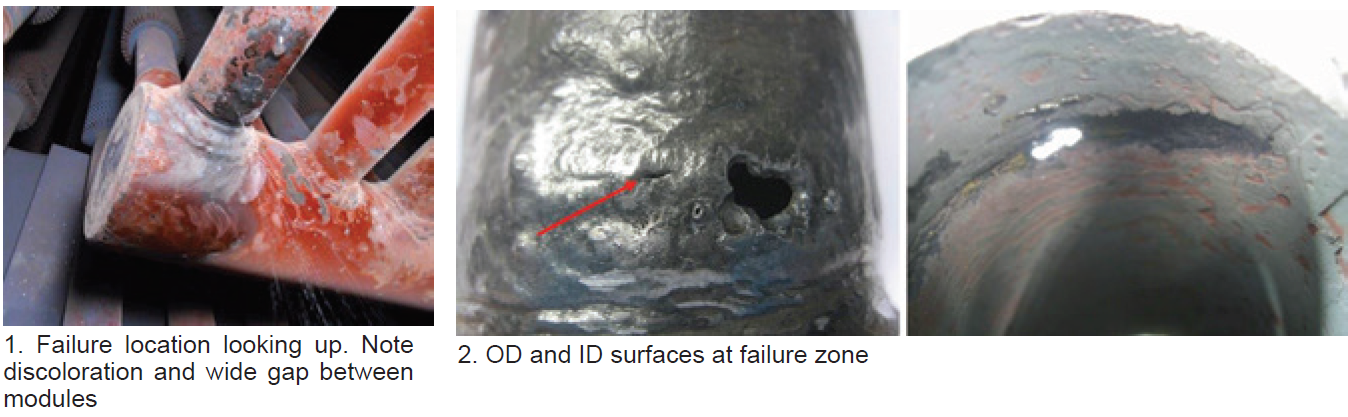

This presentation of a unique reheater-tube failure mechanism may be the precursor of many future mid-life failures in other HRSGs. The tube adjacent to the gap between modules, and entering the lower outlet header horizontally, had clearly overheated as shown by the large internal oxide growth and exfoliation data base (Figs 1 and 2).

Metallurgical reports showed multiple circumferential and transgranular cracks at the ID of the tube, beyond the heat-affected zone, progressing toward the outside.

Discussions and details led to observations of progressively more rapid localized oxide growth and exfoliation (OGE). Various hypotheses and further analysis steps were reviewed. The key takeaway was the following proposed sequence of events:

1. Normal steam-side oxide growth during years of operation.

2. As oxide thickens and insulates the tube internal surface from the steam, tube metal temperature increases, as does the oxide growth rate.

3. Tubes adjacent to the mid-module and sidewall gap operate hotter, and grow oxides faster than other tubes.

4. Eventually the oxide buildup reaches a critical thickness and it exfoliates.

5. In the case described, exfoliated oxide plugged, or partially plugged, the horizontal section of tube resulting in severe overheating.

6. Severe overheating and thermal-transient-driven strain at the failure site further accelerated localized OGE, thinning the tube wall and resulting in failure.

Learn more about this failure and OGE from Dooley at the upcoming HRSG Forum with Bob Anderson, July 22-25, 2019, in the Hilton Orlando.

Inspection after four years. A comprehensive presentation was given on pressure-vessel inspections at a combined-cycle plant after four years of operation, covering all major systems and their components.

The unit’s cycle chemistry includes all-ferrous feedwater metallurgy, AVT (O), solid alkalizing agent added to the HP and LP evaporators, no condensate polisher, and low iron level in the feedwater. Inspection methods, including commissioning and beyond, were described.

First in-service inspections (2015) showed loss of wall thickness in the HP economizer headers (one unit) and cracking in HP and LP drums (second unit), two-phase FAC in the condenser, and liquid impingement erosion of L-0 turbine blade row and shroud.

Water-chemistry management was reviewed, revealing a lack of trained personnel, lack of water-chemistry documentation, insufficient sampling and testing, and insufficient instrumentation to meet the recommendations of IAPWS published in its TGD 2-09. Improvements began, and by 2018, water-chemistry management was considered “close to normal.”

With chemistry management improved, the plant will concentrate on more active in-service inspections, and a proactive risk-based analysis approach.

HP drum replacement. The conference organizers called this “A great example of successful significant HRSG plant engineering projects—specifically, a total HP steam-drum replacement in a triple-pressure unit with key learnings outlined and shared.”

The HP drum at Tallawarra in Australia was replaced in 2018, after cracks were discovered in 2013 (just four years after commissioning). Deep cracks were discovered in various parts of the drum (risers and downcomers).

The cracks aligned with the fusion line between the weld and the drum and were determined to be blunt and oxide-filled, most likely the result of original welding defects—for example, a lack of sidewall fusion in the weldment to parent material.

The repair option was considered, but would mean a long outage (112 days). Even then, there was risk of not fully resolving the issues. This option was declined. Tallawarra was determined safe to operate (with adjustments) in the short term, and drum replacement planning began.

The challenges. An intensive two-year program was set that included factory visits and documentation reviews, stringent weld procedure and welder qualification checks, material certificates, reviews of heat treatment and hydrostatic test procedures, and clearly defined hold points.

Site preparation included risk-assessment workshops (including health and safety) and mitigation strategies based on workshop outcomes. Material handling challenges included a ground-to-height distance of 100 ft, anchor points with drone location reviews, and physical separation of multiple working levels (three above the drum floor, one below). Height restrictions from a nearby airport called for adjustments to the lift plan.

A key takeaway from this presentation was lessons learned. Engaging contractors in the work-assessment workshops was given high marks, as were real-time opportunities for safety strategies and improvements.

The drum was replaced within the scheduled period of 58 days.

An attendee with relevant experience told the editors afterwards that the drum-replacement plan presented certainly was one a similarly affected user might consider—provided his or her site could accommodate the cranes necessary to remove and replace the drum.

However, he said, he was not aware of a crack in a properly constructed drum-nozzle weld that has required replacement. While there are a lot of in-service cracks being found, the participant continued, he believes all have been successfully managed and/or repaired without removing/replacing the nozzle—thus far, anyway.

Editor’s note: ABHUG is supported by the International Association for the Properties of Water and Steam (IAPWS) and held in association with the European HRSG Forum, the HRSG Forum with Bob Anderson, and the journal PowerPlant Chemistry.