Costly fogging-pump failures and consequent maintenance repairs had negatively affected Fremont Energy Center’s summer peak season performance and its maintenance budget. Plant personnel realized the need to prevent premature pump failures and avert costly fogging-system downtime.

The plant maintenance staff began investigation of multiple issues linked to premature failures of the station’s fogging pumps. In the process, personnel learned that the low lubricity of demineralized water was causing pump seals to fail.

They devised a plan to upgrade the fogging system. It included the use of service water to flush pump seals, thereby cooling and lubricating them. This was accomplished by retrofitting all of the fogging pumps with flushed manifold heads. The result was increased seal life plus dramatically lower maintenance cost and fogging-system downtime.

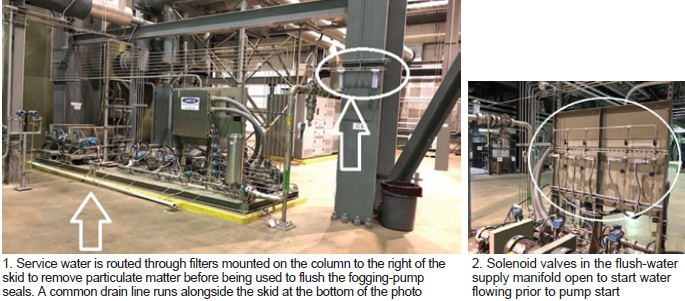

To implement this solution, the maintenance staff and site engineer hot-tapped the service-water headers for flushing liquid, routed the service water through two particulate filters to a manifold near the fogging skid, and branched off those lines to each of the pumps (Fig 1).

Technicians then installed solenoids on the service water supply and tied them into the fogging-pump start logic to begin supplying flushing water before the fogging pumps start (Fig 2). Lastly, they tied drain lines from each pump into one common plant drain (refer back to Fig 1).

This solution saves the 501F-powered 2 × 1 combined cycle approximately $100,000 annually by reducing fogging-system downtime and increasing power output. Steve Greene is the plant manager for operator NAES Corp.