Mashav Energy

Owned by Mashav Initiating & Development|

Operated by Mashav Energy

122 MW, 2 × 1 LM6000PF-powered combined cycle with a Siemens 300 steam turbine/generator, located in Ramia, Israel

Plant manager: Yohay Aviguy

Challenge. Water is the lifeblood of powerplants, especially those located in desert environments. Every effort must be made to conserve this important resource. Mashav Energy focused on these three areas:

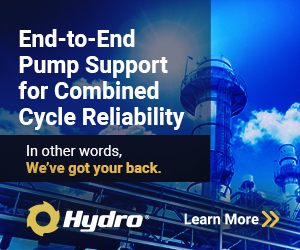

- Reuse of blowdown from cooling towers serving the gas-turbine air inlet chillers (Figs 1 and 2).

- Recovery of water from the steam-quality monitoring system (Fig 3).

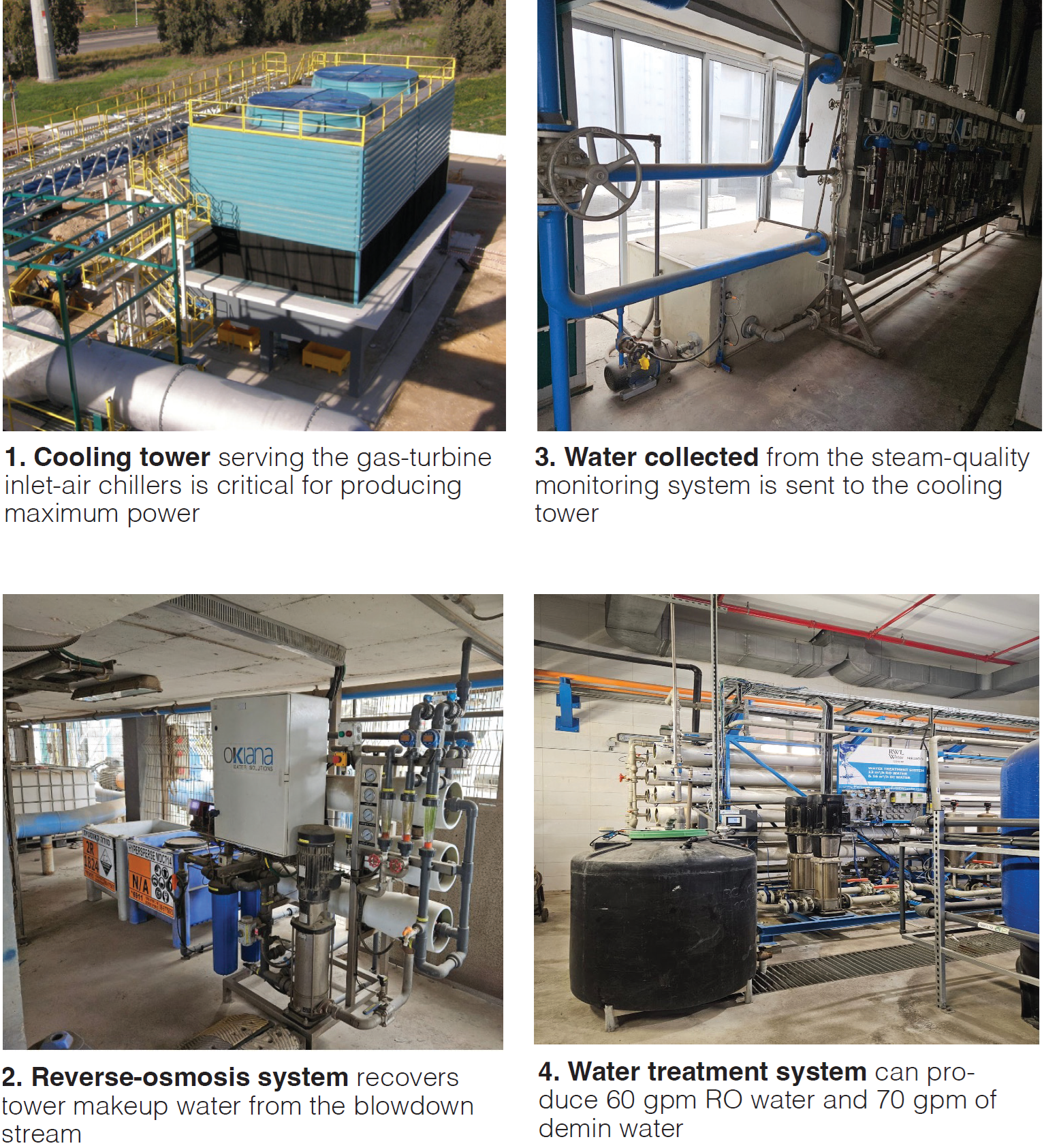

- Recovery of water from desalination-plant instrumentation (Fig 4).

Solution:

- Blowdown from the two-cell cooling tower, totaling about 3.3 million gallons annually, first was sent to a collection tank and then piped to a nearby cement plant for process use. Looking for a better application of the resource, plant opted to install a small reverse-osmosis (RO) system to recover about 50% to 60% of the blowdown stream for cooling-tower makeup (30 µS conductivity and 9 pH). Reject water from the RO system is pumped to the cement plant for process use as before.

- Water collected in a small tank from instrumentation in the steam-quality monitoring system is pumped to the cooling tower.

- Water from instrumentation in the desalination plant are collected and pumped back to the potable-water holding tank which serves as a reservoir for the desal plant.

Results:

- Payback for the RO system recovering water from the cooling-tower blowdown stream was only 14 months. The system now is in its third year of service.

- All water used in the monitoring of steam quality is recovered.

- Water recovered from instrumentation serving the water treatment system shown in Fig 4 totals about 1.6 million gallons annually. The system provides, in round numbers, 60 gpm of RO-quality water and 70 gpm of demineralized water.

Project participant:

Yohay Aviguy, plant manager