Essential Power Newington

Owned by Essential Power Investments

Operated by Cogentrix Energy Power Management565 MW, 2 × 1 7F-powered combined cycle equipped with a GE D11 steam turbine, located in Newington, NH

Plant manager: Tom Fallon

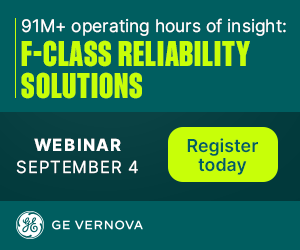

Flags make HV grounds visible to ensure proper installation

Challenge. During maintenance outages when conducting high-voltage (HV) activities, personnel work diligently to be sure grounds always are under “control.” Site philosophy is that grounds are the last items on the LOTO and the first off it when restoration activities are conducted. A site-qualified electrical employee always will sign onto a LOTO that contains grounds so he or she can witness attachment/removal. The biggest challenge is making sure grounds are visible during installation to be sure there are no questions about what equipment is properly grounded.

Solution. Staff analyzed options for improving safety as well as visibility to the ground cables when they are installed on the 345-kV transmission lines during transformer testing or generator work (Fig 1). They found a supplier of all-weather, high-visibility reflective ground flags that can be hook- and loop-fastened to the ground clamp, or have a grommet-reinforced hole for zip-tying the connection to the clamp or cable.

Drawing attention to these HV ground connections adds a layer of protection to the LOTO process to ensure the grounds are properly removed before restoring the system. The flags also make it easier for contractors to know which piece of HV equipment they should be working on, given that all transformers look the same. This is a quick visual indicator to confirm you’re at the correct location without checking markings on the units.

Results. Using visual stimuli to let electrical testing contractors, equipment operators, or other personnel in the area know that the equipment is under grounds control, helps to eliminate errors. Plant’s electrical testing contractor said it hadn’t seen anything like this at any of the other plants they have performed testing services for in New England. Staff submitted this as an internal best practice within Cogentrix so the entire fleet is aware of the product and its ease of use, as well as its enhancement of awareness.

Project participants:

Chad Harrison, maintenance manager

Mike Dill, I&E technician

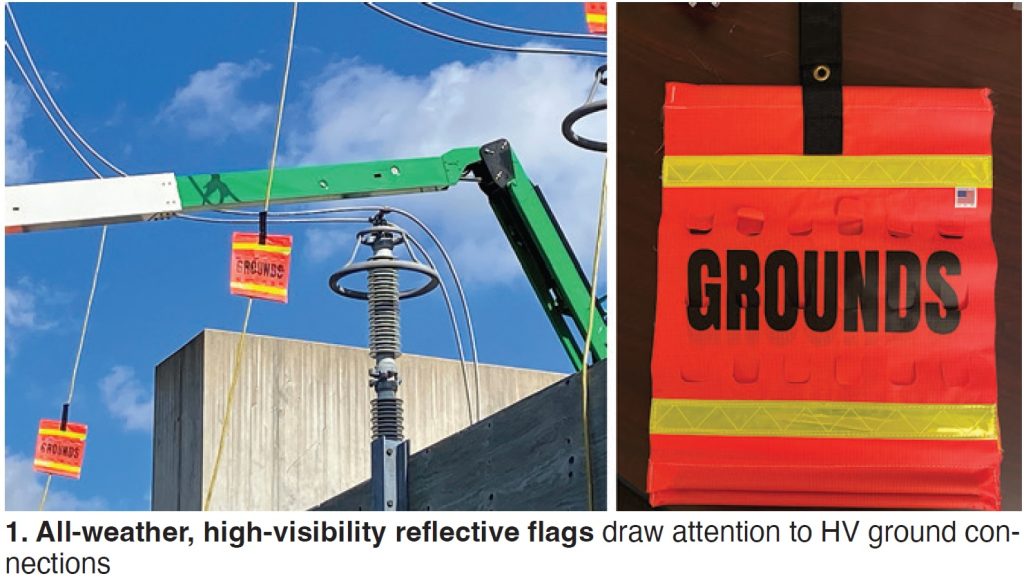

Enhanced thermal monitoring helps protect critical equipment

Challenge. Extreme cold weather is no stranger to Newington and the New England area. For a cycling facility, Newington was designed and constructed with less-than-adequate measures for cold-weather mitigation. Over the years, the facility has been improved in this regard with additional buildings, HVAC equipment, and heat-trace and insulation—with proven success during extreme cold weather.

It was important for plant personnel to learn from recent regional cold-weather events—such as the Polar Vortex of 2013/2014, Bomb Cyclone of 2015/2016, and Winter Storm Elliott during Christmas 2022—to better prepare for future storms. For example, having the ability to monitor remote locations and equipment from the control room was a necessity.

Use of remote temperature monitoring devices would be a beneficial freeze-protection addition and would complement the site’s cold-weather plan in a pronounced way. This was particularly important given NERC’s plan (at the time) to revise standard EOP-11, “Emergency Preparedness and Operations” and mandate that generation owners implement a cold-weather preparedness plan.

Solution. When sharing internal best practices with another asset in the Cogentrix portfolio, Newington personnel investigated a remote temperature monitoring solution called Monnit®. After developing an implementation plan, Monnit sensors were ordered and installed.

The sensors have the ability to check-in at any periodicity the user desires and can proactively alert others via email and text of cold/hot areas of concern. Data captured by each sensor can be trended, an important capability. With the iMonnit software and affordable licensing, users can monitor the entire network of sensors from one location—such as the control room. There also is a cell-phone app that can be downloaded and monitored as needed.

Newington purchased several lithium-battery-powered industrial-grade remote temperature sensors for temperature-critical areas (Fig 2), such as the following:

- Fire sprinkler/deluge buildings.

- HRSG internal sections.

- Critical instrumentation boxes.

- Feedwater piping susceptible to freeze-up during offline periods.

- Auxiliary equipment outbuildings.

Results. With the installation thus far of 38 sensors facility-wide, Newington has the ability to monitor and be alerted on critical areas of concern during extreme cold and hot weather events. Reports can be generated from the software and rules established to automate device concerns, battery levels, or area temperature cold and/or hot thresholds.

These devices were an added feature in the facility’s new NERC cold-weather awareness plant in support of EOP-011-2, which became effective Apr 1, 2023.

Project participants:

Joshua Leighton, operations manager

Eric Pigman, engineering manager

Cogentrix’s Hamilton Liberty staff

Cogentrix’s Hamilton Patriot staff

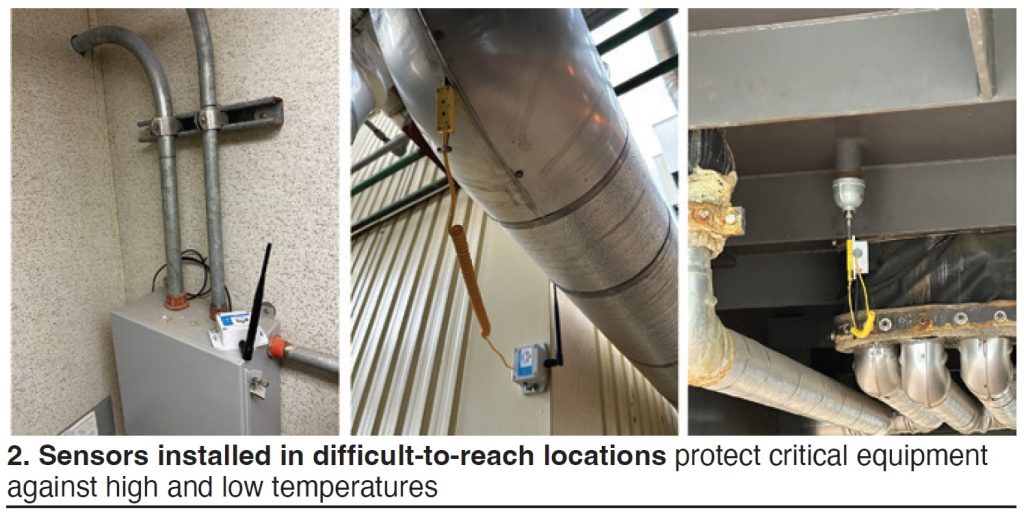

Fuel filter enhancements facilitate O&M, improve safety

Challenge. Essential Power Newington was designed to operate primarily on natural gas, with the ability to transfer to ultra-low-sulfur diesel (ULSD) as necessary. Historically, ULSD has been burned in winter when natural-gas demand and oil prices are at their peaks.

Duplex fuel filters were provided to remove particulates from the distillate fuel. A pressure gage and alarm switch monitor the differential pressure across the strainer to indicate when filter replacement is required. The filters are located in an off-package liquid fuel/atomizing air module with limited and challenging access for routine O&M. Filter-housing changeover, pressure-equalizing, and drain valves were extremely difficult to access and operate safely.

Filter replacement often was required when the unit was operating—when reliability is paramount. Operation of the various filter valves required kneeling down on a small grating platform underneath control-oil tubing with limited leverage for filter changeover and media removal. The filter was located a few feet below the grating and difficult to reach (Fig 3, left).

Solution. A site team walked down the two gas turbines and agreed on an appropriate in-house design to support filter O&M in a safe, effective manner. Valve extension handles were constructed by site maintenance employees for all drains and equalizing and filter changeover valves. The control-oil tubing for the liquid-fuel stop and bypass valves in each of the GT compartments was rerouted to improve filter access.

Results. With extension handles installed on filter drain, equalizing, and changeover valves for both units, access improved tremendously, allowing safe and effective O&M evolutions (Fig 3, right). The system was installed in fall 2022, and operated throughout the winter of 2022/2023 when liquid fuel was burned, with positive results. Avoiding a safety incident or damage to equipment by poor leverage and ergonomics was the key to this completely in-house design and improvement.

Project participants:

Scott Roy, lead plant operator

Ted Karabinas, maintenance technician

Tom Jamison, maintenance technician