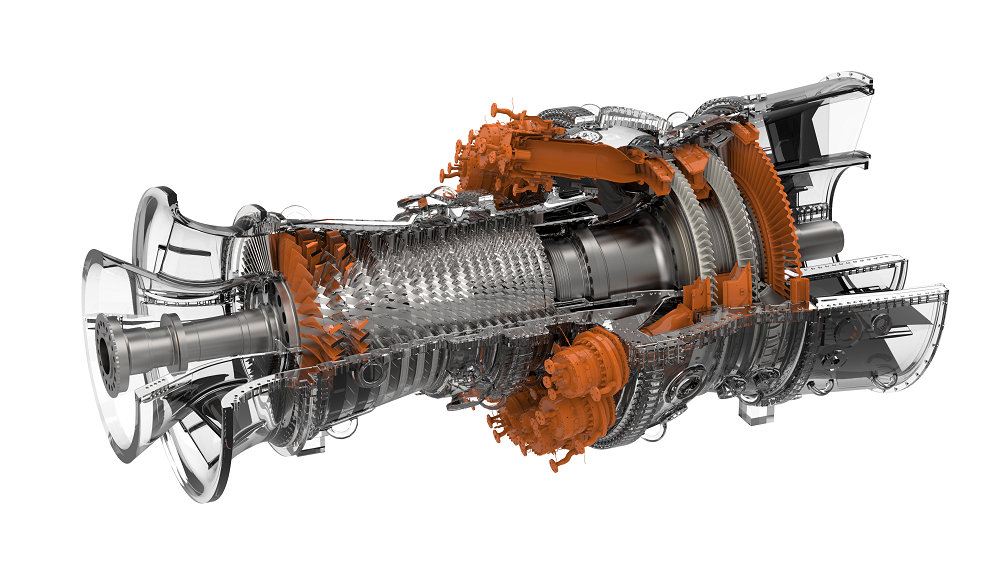

PSM’s 7F upgrade packages, which provide users the flexibility to optimize performance and maintenance schedules to their individual requirements, are covered in the second part of the session presented by Greg Vogel, senior engineering manager for technology programs, and Bryan Kalb, combustion engineering manager. Part one, outlined here, focuses on the company’s increasingly popular FlameSheet™ combustion system.

GTOP (Gas Turbine Optimization Package) supports three modes of operation—maintenance performance, and peak—and allows users to toggle among the three for optimal performance, depending on operational and business needs. Targeted hot-gas-path and compressor-part upgrades ensure a cost-efficient, reliable upgrade compatible with existing OEM 7F hardware. Remember, too, GTOP is compatible with multiple combustion systems—including FlameSheet™—to maximize the performance improvement.

Recall that GTOP 3.1 and 4.1 upgrades incorporate aerodynamically redesigned compressor parts—R0, S0, and S1—for increased compressor inlet flow and enhanced mechanical integrity. Recent installations and results will be reviewed by the speakers. Plus, the latest GTOP upgrades compatible with both 7F.03 and 7F.04 machines will be described.

New technology will be introduced as part of PSM’s GTOP4 program, which leverages the company’s experience gained in expanding its performance offerings to the 501F engine, promotes more cooling in the first stages of the turbine section. This suggests maintenance and life cycle costs with the PSM improvement may be more favorable compared to those experienced by users with the OEM’s AGP design.

PSM reminds readers of the typical performance improvements (below) recorded by installation of GTOP 3/3.1 on standard 7F.03 engines:

- Maintenance mode (32k), up to 6%

- Performance mode (24k), up to 8.8%

- Peak mode, up to 11.7%

Performance improvements possible with GTOP 4/4.1 will be presented at the 7F Users Group meeting—another reason to attend.