Pinelawn Power LLC

Owned by J-Power USA Operated by NAES Corp

80-MW, dual-fuel, 1 × 1 combined cycle located in West Babylon, NY

Plant manager: Kenneth Ford

Infrared camera finds steam leak

Infrared camera finds steam leak

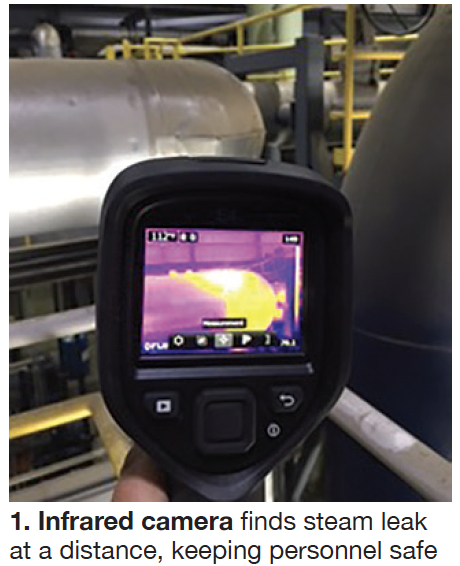

Challenge was to find the location of a steam leak on insulated and covered high- pressure steam piping. The leak was a minor one and initially identified by condensed moisture dripping from a seam on the insulation covering. The site hoped to locate the leak without jeopardizing the safety of plant personnel and having to remove a large amount of insulation and associated covering.

Solution. The site deployed its infrared camera (initially purchased to aid in identification of electrical hotspots) to pinpoint the leak location. From a safe distance, the infrared camera was used to scan the surface temperature of the insulation (Fig 1) and quickly find the leak. Once the piping was cool, staff removed the insulation in the affected area to reveal the small weld defect responsible.

Results. Use of an infrared camera to locate the leak reduced the hazards to involved personnel and also helped reduce restoration costs by minimizing the amount of insulation requiring removal.

Project participants: Mark Whitney, O&M manager

Utility cart ladder/accessory rack fabrication, installation

Challenge. The site utility cart manufacturer did not offer an option for a ladder/accessory rack. Staff wanted to increase the utility of the cart by including provision for safe transport of ladders and other tools/equipment. Personnel had to ensure that any addition to the utility cart would not interfere with its tilting-bed feature or exceed the carrying capacity.

Challenge. The site utility cart manufacturer did not offer an option for a ladder/accessory rack. Staff wanted to increase the utility of the cart by including provision for safe transport of ladders and other tools/equipment. Personnel had to ensure that any addition to the utility cart would not interfere with its tilting-bed feature or exceed the carrying capacity.

Solution. Site OMTs designed, fabricated, and installed a custom ladder rack out of aluminum square tubing. Aluminum was chosen for its superior corrosion resistance, low weight characteristic, and ease of construction.

Results. Addition of the ladder/accessory rack (Fig 2) has significantly improved the usefulness of the cart and simultaneously created a safer work environment for site personnel by decreasing the need for manual carrying of ladders, tools, and other equipment to work locations throughout the plant.

Project participants: Frank Pagano and John Stral, OMTs

Add storage rack to forklift

Challenge. Site personnel identified an unsafe work practice whereby the floor of the site forklift could potentially be used to transport tools, rigging, or other equipment, thereby obstructing free and clear access to forklift foot pedals and impeding operator entry/egress.

Solution. Plant technicians designed, fabricated, and installed a removable storage rack made of aluminum square tubing. The rack was designed to accommodate two portable tool totes. Aluminum was chosen for its superior corrosion resistance, low weight characteristic, and ease of construction.

Results. Addition of the storage rack to the forklift has improved its usefulness by converting previous “dead” space into new storage space and simultaneously creating a safer work environment for site personnel by decreasing the chances that staff would be tempted to use the floor of the forklift for transport of tools or equipment.

Project participants: Frank Pagano and John Stral, OMTs