Steve Shulder, EPRI’s subject matter expert on water and steam chemistry addressed chemistry-related damage from flexible operations during Week Four of the CCUG2020 program. Thorough to a fault, most of Shulder’s slides are laden with bullet points, likely summarizing chapters of EPRI reports on the subject. It’s almost impossible to condense the 45-slide deck into useful highlights, so users should both review it and watch the recording on the Power Users website. The presentation is packed with good material for whoever is responsible for plant chemistry.

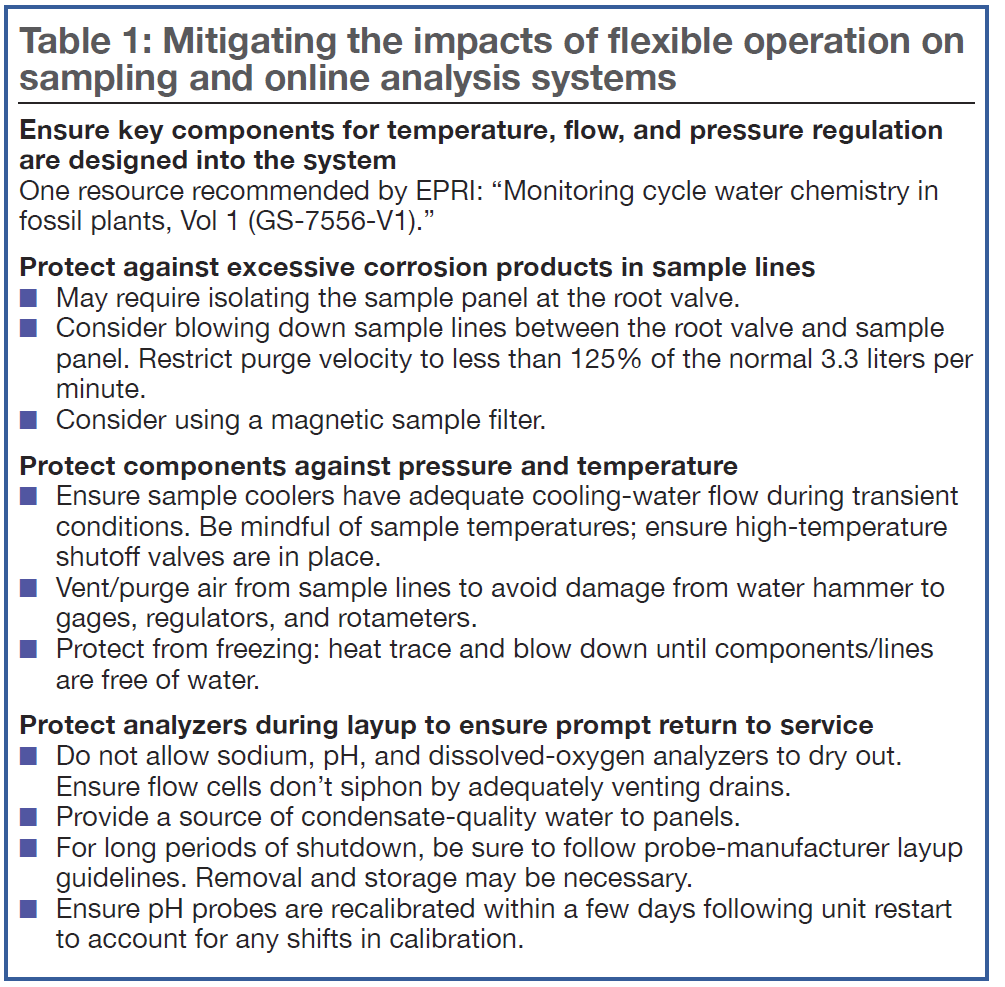

Two areas worth reviewing here, however, are (1) maintaining sampling and online analyzer systems and (2) plant layup and storage. Keeping the former in top working order is critical because, during operation, “you can’t control what you can’t see,” stressed Shulder.

Of course, online analyzer systems are also impacted by cycling operations and improper layup. Debris in the water/steam circuits can plug sample lines. Sample lines should be equipped with blowdown lines; lines and analyzers should have de-ionized water flowing through them so they don’t dry out. Other checklist items are shown in Table 1.

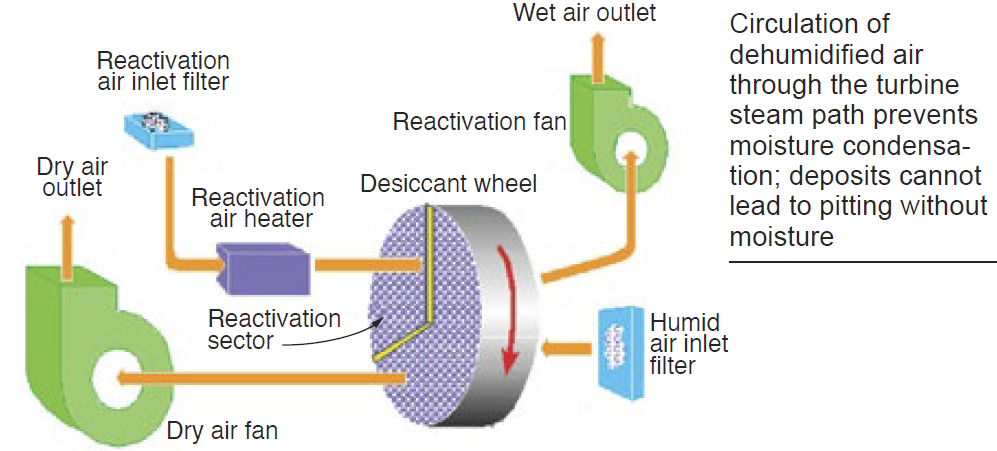

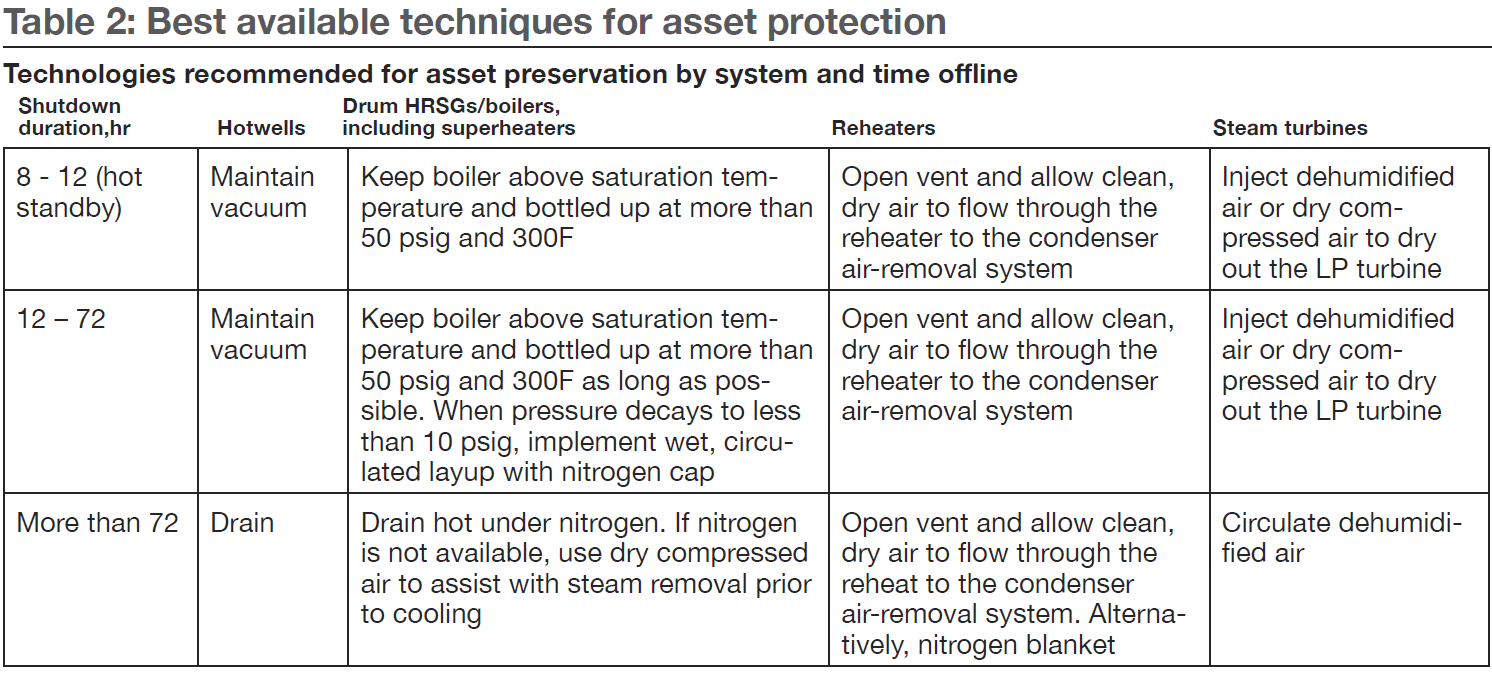

The table on best available techniques for layup and protection (Table 2) is a convenient guide organized by plant subsystems and components. Of note as well is a recently developed dehumidified-air system (figure), proven at several combined-cycle plants in the south, which protects the turbine steam path from moisture condensation when offline for long periods. “Deposits cannot lead to pitting without moisture,” Shulder reminded the audience.