If you never had responsibility for operating and/or maintaining a GE E-, F-, or H-Frame gas turbine you might not have met Schuyler McElrath, who left us in mid-January at the age of 66. He was a fuel-system expert, always available to help users keep their engines starting and running reliably on oil. He was by far and away the industry’s most visible fuel-system problem solver, having acquired his considerable knowledge and honed his skills over nearly 25 years with GE.

He brought that unique background to JASC two decades ago as an independent contractor after meeting founder Harvey Jansen. The two men had a special synergy: Schuyler understood well the fuel-system issues tormenting gas-turbine owner/operators while Harv and his team at JASC provided the creative genius to engineer the needed flow-control solutions based in large part on the company’s work developing space-age components for the aviation industry. Both men had a passion for the mission they embraced and together they made good things happen.

The editors remember Schuyler as a very private man who focused on work, faith, family (wife Sylvia and two daughters), and fishing. We chatted with him at virtually every industry meeting for users of GE turbines over the last two decades. On-going discussions were not of a personal nature, but rather about technical issues associated with the use of liquid fuels and their solutions. He shared much of this work with CCJ’s audience in print and online.

Schuyler’s considerable health/physical challenges were not even a footnote. One can only imagine the immense effort it took for him to navigate meetings and industrial facilities via motorized scooter, juggle schedules to accommodate his many operations and hospital visits, get to and from places he believed he had to be to see customers in person—including the Middle East only a couple of months ago—etc. Never a thought of throwing in the towel, never a whimper. Always a smile. He was a very special person.

Our education began back in 2005 or early 2006. Given the complexity of the issues facing owner/operators of frame machines with respect to fuel systems, he told us in that first sit-down, “the solutions are amazingly simple.” The primary cause of liquid-fuel-system failures, he said, is check valves that stick open, stay closed, or remain somewhere in between after the gas turbine runs for long periods on natural gas.

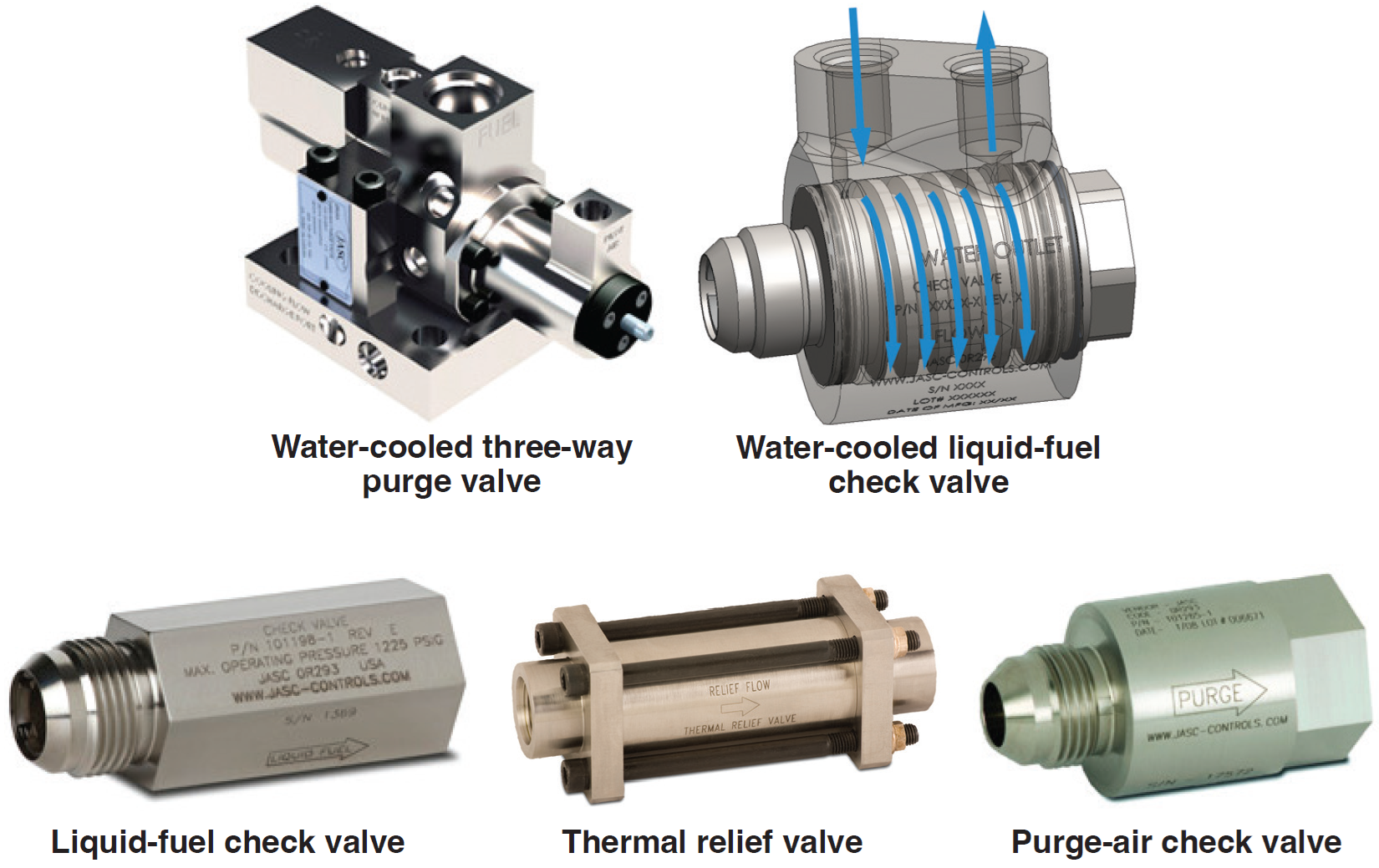

Specifically, the high temperatures around combustion cans “cook” the fuel inside the valves, promoting the buildup of a hard residue which inhibits valve operation. JASC solved this problem by designing a liquid-fuel check valve that resides within an external water jacket.

The editors were asked by Harv to proof-test the idea on a visit to JASC’s shop. He put a valve in an oven at 500F and turned on the cooling circuit. Then he opened the oven door and, with a grin like that on the proverbial Cheshire cat, asked us to touch the valve. Having been schooled in the safety-first mentality of power users, that took a leap of faith.

First commercial use of the water-cooled check valve was at an East Coast refinery with two oil/gas-fired Frame 6 machines. From commissioning through the first six years of operation with standard check valves only two of 50 fuel transfers were successful. Water-cooled check valves were installed and over the next two years the success rate for transfers from gas to oil and vice versa was 100%. Longest run on gas was three weeks.

That success encouraged the development of JASC’s product line for the electric power industry, today including the water-cooled three-way purge valve which combines the company’s liquid-fuel and purge-air valves in one unit. Several JASC products, installed in hundreds of gas-turbine fuel systems worldwide, are shown nearby. CCJ