Vanquish varnish to improve gas-turbine reliability

By James Hannon, ExxonMobil Lubricants & Specialties Co, and Andrea Wardlow, ExxonMobil Research & Engineering Co

Gas turbine owner/operators know that varnish can have a significant adverse impact on engine performance. However, there had been little formal research conducted on the problem until recently.

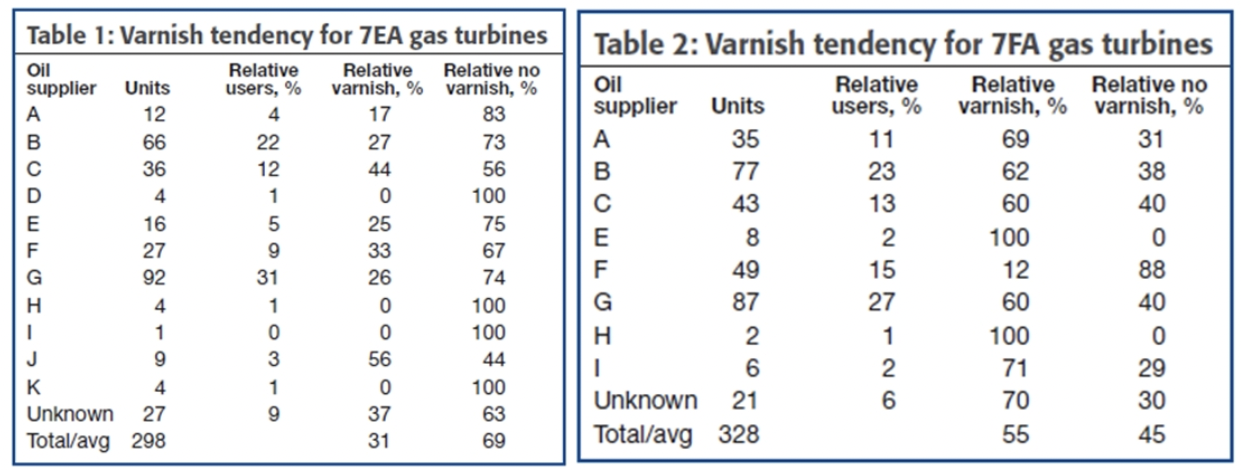

According to an ExxonMobil Lubricants & Specialties survey of 192 US powerplants with a combined total of 626 gas turbines, approximately 40% of those generating facilities reported current or historical varnish issues within six years of oil service life.

Electric-power industry sources estimate today’s cost of a utility trip or no-start to be as high as $100,000 per event. This is expected to increase dramatically as turbines are dispatched to support renewable energy generation. In refineries, the economic impact of a turbine trip or no-start can be measured in millions of dollars per event.

Turbine owner/operators know that varnish can have a significant adverse impact on engine performance. However, there had been little formal research conducted on the problem until recently.According to an ExxonMobil Lubricants & Specialties survey of 192 US powerplants with a combined total of 626 gas turbines, approximately 40% of those generating facilities reported current or historical varnish issues within six years of oil service life.Electric-power industry sources estimate today’s cost of a utility trip or no-start to be as high as $100,000 per event. This is expected to increase dramatically as turbines are dispatched to support renewable energy generation. In refineries, the economic impact of a turbine trip or no-start can be measured in millions of dollars per event.

What is varnish?

Varnish is a catch-all term for deposits (Fig 1), either in the form of sludge or varnish. Here, varnish refers to both sludge and varnish unless otherwise specified. Sludge is a soft, pliable, organic residue that can be easily removed by wiping, while varnish is a hard, oil- insoluble organic residue difficult to remove by wiping. Varnish and sludge are formed in different ways after an oil’s additive components and/or base stock decay.

Turbines with common control- and bearing-oil reservoirs are far more susceptible to unit trips or no-starts related to varnish than turbines with segregated reservoirs. In common-reservoir systems, which are those that rely on a single reservoir and oil to meet bearing and hydraulic needs, the same turbine oil that is used to carry the bearing load at elevated temperatures must also flow through 3-micron-tolerance servo valves.

Turbines with common control- and bearing-oil reservoirs are far more susceptible to unit trips or no-starts related to varnish than turbines with segregated reservoirs. In common-reservoir systems, which are those that rely on a single reservoir and oil to meet bearing and hydraulic needs, the same turbine oil that is used to carry the bearing load at elevated temperatures must also flow through 3-micron-tolerance servo valves.

The turbine oil, which is supplied to these servo valves via external tubing, often is not circulating during unit shutdown and will cool. As the oil cools, insoluble products of oxidation can come out of solution and subsequently foul the hydraulic elements. These cooler, low-flow, tight-tolerance areas are the most prone to varnish problems.

By comparison, steam- and gas-turbine journal and thrust bearing clearances are around 200 microns. Mild varnish can build on journal and thrust bearings with little or no impact on bearing temperatures or shaft rotation. Unit trips or no-starts attributed to varnish rarely, if ever, are reported. For these reasons, varnish prevention and detection is focused on turbines with a common control- and turbine-oil reservoir.

Example: The GE Frame 7FA gasturbine has a 6400-gal oil reservoirthat supplies the turbine and generatorbearings, seal oil, and system hydraulics at a full flow rate of 700g pm. Flow to the hydraulics, suppliedthrough secondary booster pumps,represents less than 1% of the total system flow. However, it only takes a small amount of varnish to cause hydraulic-filter fouling or servo-valvespool sticking. Sludge or varnish thatmight form in the hydraulics could be less than one ounce.

An ounce ofvarnish in this system is equivalent to one ppm, which may seem insignificant,but isn’t.In turbine models dating backto the early 1990s, air-to-fuel ratioswere not as precise as required by today’s standards. More stringentenvironmental regulations led toinstallation of dry low-NOx combustors,which, in turn, called for greater servo-valve precision and little tolerance for valve sticking. On today’sturbines, when the servo-valve position does not meet valve command, the turbine can, and often will, trip.

Elevated firing temperatures, aging gas turbines, andincreased cycling also contribute to varnish issues. Some believe, incorrectly, thatincidents of gas-turbine hydraulic varnish issues have increased with new-technology turbine oils. However, direct field experience, combined with test-rig oil comparisons, confirms that some turbine-oil formulations are clearly better than others.

Varnish theory

While peaking and cycling plants typically have a much higher potentialfor varnish-related issues, the survey revealed that some peaking and cyclical plants have no problems, while some base-load plants do survey, a turbine identified as having varnish had experienced physical varnish-related issues.A turbine with no physical varnish or varnish-related issues, but tested by oil analysis as showing elevated varnish, is classified as no varnish/varnish. It is interesting to note that varnish formation transcends both past and current turbine oils tested. The question becomes, “Why are some turbines more susceptible to varnish issues than others?” Varnish formation mechanisms can be broadly categorized as thermal degradation, oxidation, and contamination, as defined below:

Thermal degradation is molecular cracking that takes place at temperatures above 570F. For example, electrostatic discharge (ESD) caused by arcing across filters can generate 1830F localized temperatures. Likewise, adiabatic compression, also called micro-dieseling, can generate 1100F localized temperatures.

Oxidation is the decomposition of oil in the presence of oxygen. It is accelerated by exposure to temperatures of 480F and above. Oxidation occurs at lower temperatures, but the reaction is slower. It is possible for oxidation to occur at bearing surfaces.

Oil can be contaminated from both external and internal sources. External contamination is often the result of poor turbine system flushing during the commissioning or by reuse of the flush oil. Some rust preventatives can oxidize turbine oil prematurely. Internal contamination is described as sub-micron oxidized oil that agglomerates to leave deposits.

Certain oil additives are can create more varnish than others—including some rust inhibitors. Different turbine oil base stocks (API Group 1, 2, 3, and 4) are an important consideration, too. Each has its own positives and negatives. Oxidation stability often improves with base-stock classification while varnish solubility declines. Quality levels within base-stock categories also vary, so specific base-stock selection within a group is very important.

Mixed reservoirs of two different oils may contribute to the formation of varnish because of additive incompatibility. Use of ASTM D7155, “Standard Practice for Evaluating Compatibility of Mixtures of Turbine Oils,” is a suitable screening tool. Keep in mind that base oils may be compatible, but the additives may not be. Your lubricant supplier can help identify incompatibilities. Varnish formation also is influenced by operating variables such as ambient and bearing temperatures, system flush, turbine-oil chemistry, filter selection, and hydraulic system pressures.

Attempts have been made to add aftermarket chemistry to in-service turbine oil to control varnish formation without replacing oil. This practice is not recommended. If the turbine oil is deemed unfit for continued service because of varnish formation, a varnish flush as outlined in ASTM D 6439, “Standard Guide for Cleaning, Flushing, and Purification of Steam, Gas, and Hydroelectric Turbine Lubrication Systems,” is a far better option.

Find the right turbine oil

Lube oils with highly refined base oils and a proper balance of advanced-technology additives are less likely than alternatives to be compromised during long-term service. You need to evaluate a lubricant’s deposit control, oxidation stability, air release and foam control, filterability, rust and corrosion and wear protection.

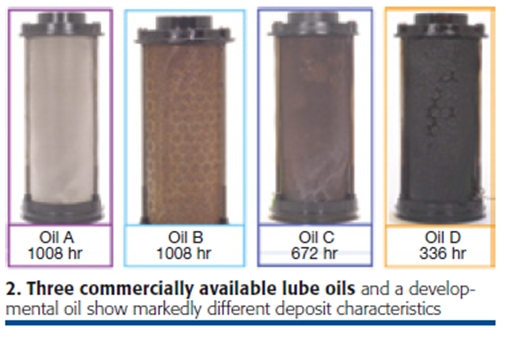

Advanced turbine oils are formulated to limit the production of sludge and varnish, while keeping deposits in suspension. Deposit formation can be measured and readily observed in rig testing (Fig 2).High temperatures, combined with metal particles, contaminants, and entrained air, all contribute to oxidation. Higher-level turbine-oil base stocks and advanced antioxidants, when properly formulated, protect against oxidation.

Entrained air in oil with inferior air release may be compressed in turbine bearings or high- pressure hydraulics and result in adiabatic compression, which can elevate local oil temperature and promote varnish formation. In addition, inferior air release impairs system hydraulics. Excessive surface-level foaming can accelerate oxidation and cause operational issues—such as the inability to measure lubricant levels correctly, or cause reservoir overflow from vents.

An oil with poor filterability will foul filters faster that an oil with good filterability. Consequence of the latter is more frequent filter changes. Rust and corrosion also can contribute to oxidation and the formation of contaminant-based varnish. Finally, wear on high-pressure hydraulics and on the gears of the accessory gearbox, generator reduction gear (not installed on Frame 7s), or turning gear can be a source of varnish formation. Metal particles act as an oxidation catalyst.The concept of a balanced formulation is best understood as an optimization process. The most important attribute of a low vanish/sludge oil is deposit control.

Advanced testing

Test rig research is superior to glassware testing. The Valve Varnish Rig Test (VVRT), for example, simulates real world service and varnish formation, and consequences like servo-valve sticking. It uses hydraulic components typical of a gas turbine that are cycled with servo-valve movements to simulate startup and shutdown.

Voltage measurements are made during valve extension and retraction. Voltage signals are compared with response time, overshoot and undershoot. High varnish forming oils show stick slip friction and valve hunting at fewer operating hours than low varnish forming oil. Test-rig components also are physically examined for signs of varnish and turbine-oil degradation.

Rig testing goes beyond industry standards such as ASTM D2272, “Standard Test Method for Oxidation Stability of Steam Turbine Oils by Rotating Pressure Vessel,” or ASTM D943, “Standard Test Method for Oxidation Characteristics of Inhibited Mineral Oils.” Candidate turbine oils should, at a minimum, exceed OEM and new-oil acceptance standards, but additional field-simulated rig testing may offer the best indication of success.

In-service testing

Once the appropriate lubricant is selected, in-service performance must be monitored through a proactive oil analysis program. Generally, sampling and testing should be done at least quarterly, more frequently as the oil condition degrades. Trending results gives maintenance personnel valuable insights into the condition of the oil, the condition of the equipment, and the remaining service life of both.

Today’s common oil analysis testing methods—including ASTM D2272, total acid number (TAN) increase (ASTM D664), and ISO Cleanliness Code 4406—do not accurately predict varnish. A superior approach is based on a combination of ultra centrifuge (UC), membrane patch colorimetry (MPC), and remaining useful life evaluation routine (RULER) based on linear-sweep voltammetry tests. All are gaining credibility and acceptance in the industry.

Action plans based on these tests should be application- and oil-specific. Application-specific action plans recognize that gas turbines with combined hydraulic and bearing reservoirs are more varnish sensitive than a steam turbine with separate hydraulics. Oil-specific action plans refer to the unique chemistry of each turbine oil. Action plans for varnish-prediction test results may be unique to each oil chemistry. More field correlation work is required.

The test results may require the use of different interpretative methods, depending on the presence of various additive components. Your lube-oil supplier can provide details on these relatively new but successful industry approaches.

Briefly, UC is a varnish prediction test. A test tube of used oil is spun at 17,500 rpm at ambient temperature for 30 minutes. The tubes are visually examined for residue and given a rating of between one and eight, with one being the cleanest. UC scores continue to correlate well with field varnish observations.

MPC identifies the contamination level in used oil related to oil degradation and potential varnish development. This test entails pulling an oil sample with a vacuum pump through a membrane nitro-cellulose patch. The resulting stain on the patch is numerically rated, based on the increased absorbency of specific visible light waves.

The RULER test identifies levels of antioxidants, typically phenols and/or amines. In-service oil antioxidant levels are compared to those for new oil. As antioxidants age, they can volatize or convert to new species that have antioxidant properties, called intermediates. These intermediates can be measured by RULER. but may require additional analysis and processing. In gas-turbine operation, phenols typically will deplete first because of temperature, followed by the amines.

Servo-valve manufacturers typically recommend that hydraulic supply oil be filtered to ISO 16/14/11. Particle counts higher than this can result in premature servo-valve wear and valve sticking. Some gas turbines with a common hydraulic and bearing reservoir have 15-micron filters upstream of the servo valve with a 60-micron filter (also called last-chance or pencil filter) in the servo valve. Often, to obtain the recommended ISO cleanliness, external side-stream filtration is used.

Action codes based on these varnish prediction techniques should be validated by actual visual component inspections because oil-specific chemistry and equipment applications will vary. During shutdown, the servo valve and last chance filters should be inspected for signs of varnish. With the servo valve removed, the spool valve and pencil filter can be pulled for inspection (Fig 4). Note that if the spool valve is removed it should be properly reconditioned prior to replacement because the spool land surface may be damaged during inspection. CCJ