If you are not a generator specialist, the things you probably need to know about stator wedges are that they hold the stator bars in the iron, there are lots of them (1200-1800), and they can loosen from age or unusual or persistent vibrations, which interrupts electrical contact, leading to spark erosion. Testing them for tightness is labor-intensive, and re-wedging, if necessary, can extend the outage by up to eight to 10 shifts.

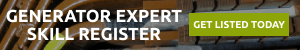

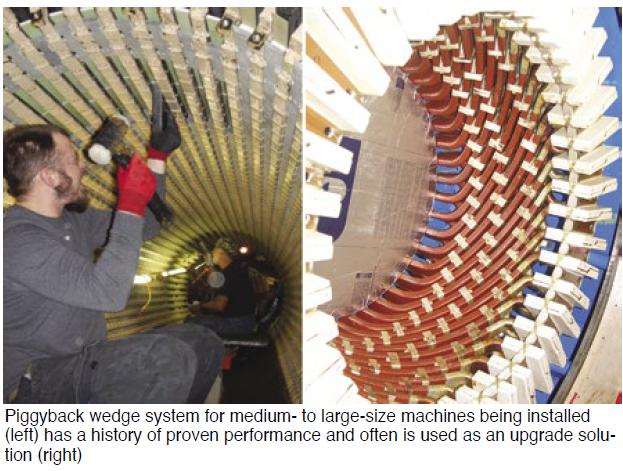

“Generator Stator Wedge Issues,” included in MD&A’s Spring 2021 Webinar Series (February 25), discussed by Generator Operations Manager James Joyce, offers a primer on the different types of stator wedges for machines made by different OEMs; inspection techniques; some of the nuances of tightening and re-wedging, such as maintaining core compression nuts at optimum torque value; and wedge-system enhancements—such as replacing flat wedges with the company’s piggyback design (photos).