Sometimes it’s best to start at the end. During Ethos Energy’s October webinar, “L-0 Blade Repairs,” Ian Saeger, manager of project engineering, concluded by stressing that last-stage steam-turbine blade repair is usually at least 50% less expensive than blade replacement and accomplished within a few weeks—if the repair can be done onsite or in-situ. The latter means with blades still attached to the rotor, the former when the blades are removed but still onsite. If blades have to be shipped to a shop, count on adding up to six months in the schedule.

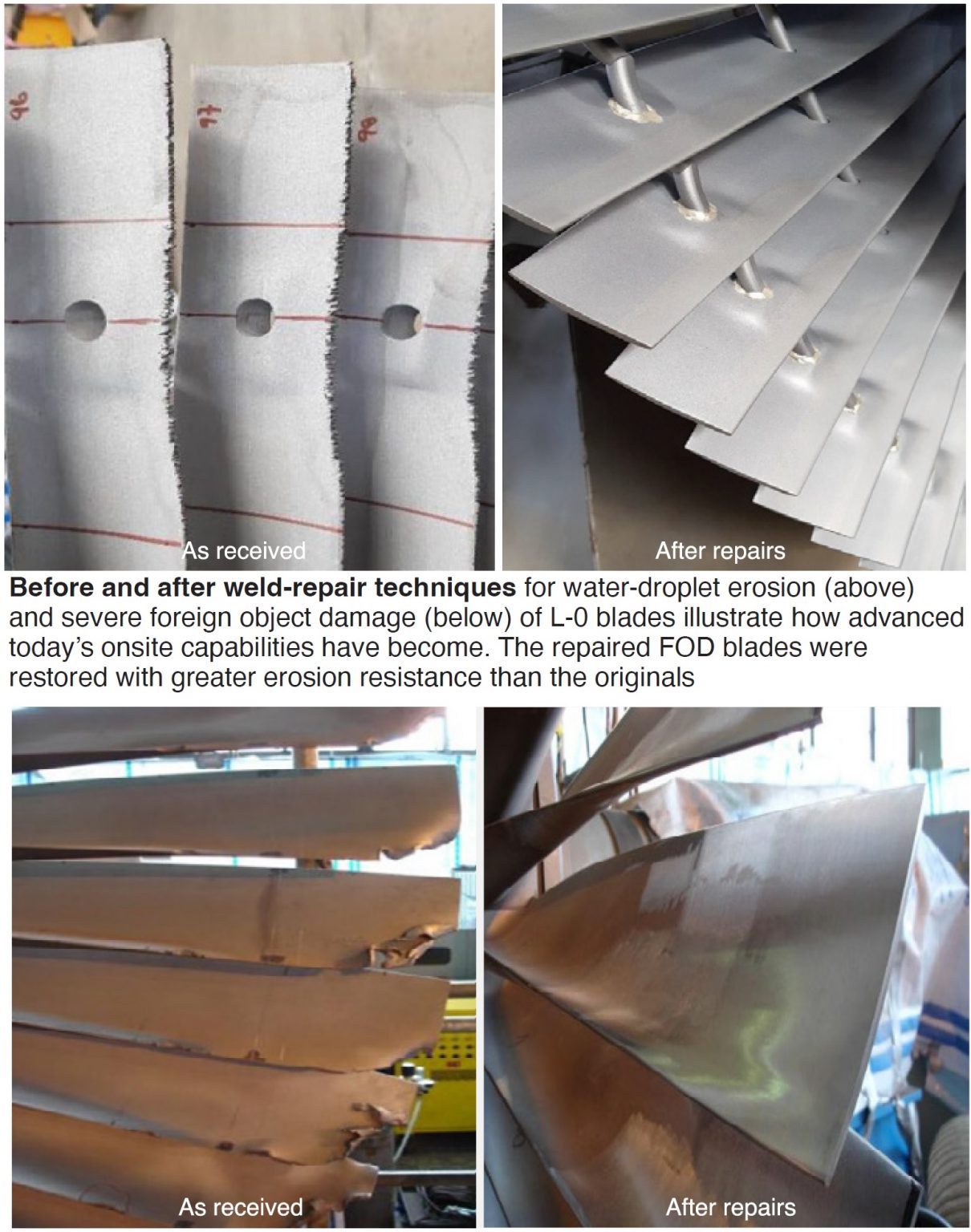

Saeger began by polling the audience on primary causes of their L-0 blade replacements. Not surprisingly, 69% responded erosion, 10% root cracking, and 21% other. He then reviewed three repair case studies involving (1) water-droplet erosion, (2) cover cracking, and (3) severe foreign-object damage (Fig).

During the Q&A, Saeger noted that most blades with a stainless-steel base can be weld-repaired. Titanium blades, on the other hand, can be welded but only in a shop vacuum furnace. However, not all blade damage is repairable. Damage near the tips generally is amenable to weld repair; damage at the base of the airfoil typically requires blade replacement.

Another useful nugget: In-situ repairs don’t generally require high-speed balancing afterwards, if done within Ethos’ specifications and airfoil geometry remains the same. When asked if there is a limit to how often a blade could be repaired, Saeger said he wasn’t aware of any limit on the frequency.

Saeger’s last slide went beyond the topic and identified solutions for D11 and A10 steam turbine/generators specifically—including the following:

- L-0 blade erosion and root cracking (see GE Technical Information Letter 1795)—40-in. L-0 root and airfoil modification. Note that the company’s repair for root cracking caused by low-cycle fatigue is a proprietary upgrade.

- N2-packing casing cracks/leakage (see GE TILs-1627-R2 and -1749)—redesigned N2 box.

- Outer-casing joint leaks—machining of outer casing joint and hardware upgrade.

- HP/IP rotor vibration/runout/bowing—rotor straightening.

- Repetitive seal failures—EEG’s Smart™ Seals.

- Diaphragm axial distortion (see GE TIL-1589)—diaphragm trailing-edge and stiffening mod.

Users (approval required) can access this recording by registering at the following link:

https://attendee.gotowebinar.com/register/8437130390099617037?source=ccj