Liberation of cobalt-based hardfacing (oft-used Stellite™ being one of these materials) from large Grade 91 valves installed in combined-cycle main and hot-reheat (HRH) steam systems, and in steam turbines, was a hot topic in the industry about a decade ago. With the need for an evidence-based solution, the Electric Power Research Institute (EPRI) assembled a committee consisting of owner/operators and stakeholders in the valve manufacturing supply chain to collaborate on the development of guidelines to mitigate the issue.

Three reports on that effort were released by EPRI in 2015 (see companion article) and the solution identified has prevented disbonding of the hardfacing where employed—at least CCJ ONsite has not identified any cases where the solution has not met expectations. Although there are only five or six years of field experience to validate the successful approach at this time, that’s a big improvement for some plants where delamination had occurred in as little as 12,000 hours of operation.

With a solution available, why is CCJ ONsite covering this topic again? The answer in brief: Not everyone who should know about this relatively recent development is aware of it. Proof of the knowledge gap came by way of a phone call from Aaron Florek of Millennium Power Services, a major player in the valve repair business, who told the editors that his firm recently had repaired valves suffering disbonding at three plants in a three-month period.

Needing confirmation that the old news (delamination) is new again, the editors contacted two technical experts with deep experience on the subject—Kim Bezzant of Utah-based Wasatch Welding Engineering Services and John Siefert, manager of EPRI’s Materials and Repair Program—as well as current users, and power-industry veteran Joe Miller, now industry director for power at ValvTechnologies Inc, which offers an alternative to Stellite hardfacing on the disks, seats, and stems of new steam valves.

All agreed that Stellite disbonding continues to haunt the industry—in large measure because owner/operators generally haven’t been diligent in upgrading their specifications both for new valves and valve repairs to reflect recent experience. It is not sufficient to simply specify that valves be manufactured, or repaired, to meet the requirements of the ASME Boiler and Pressure Vessel Code (for valves within the Code boundary) and ANSI/ASME B31.1 (for valves included with boiler external piping). Recall that these documents prescribe minimum requirements and were developed to ensure that the equipment they address is safe.

They certainly do not protect against the financial fallout from a delamination event that forces your plant offline or prolongs a scheduled outage. With all the changes to grid contractual agreements over the last few years, it is worth reviewing the exposure your plant could have to a valve failure and how much it’s prudent to spend on original equipment and repairs to insure against one.

Remember, too, it’s not enough to simply upgrade valve specifications, you have to monitor the manufacturing and repair practices of the selected solutions providers to ensure they are doing what you have carefully specified in the contract. This can be challenging where offshore vendors are involved. Boiler manufacturers and EPC firms tend to buy foreign, in particular from Korea and India, to reduce their costs and they may be reluctant to monitor contract performance in-person. Such details must be agreed to and understood before work begins.

Many boiler and turbine valves have performed admirably over the years with cobalt-based hardfacing, as well as with other hardfacing materials. But the change to Grade 91 valve bodies and the demanding operating conditions for heat-recovery steam generators (HRSGs) in combined-cycle service have pushed to the limit the technology traditionally used to bond cobalt-based hardfacing to C12A or F91 valve trim. Today’s high steam temperatures required a different methodology for attaching the two materials.

In simple terms, here’s what EPRI’s materials experts learned: Addition of a “buttering” layer of nickel-based alloy—such as Inconel™—separated Stellite and F91 material and prevented formation of an undesirable metallurgical condition in the weld zone between the two metals which is conducive to disbonding.

Plant experience. Florek told CCJ many plants in the country are addressing Stellite delamination issues and there are many more not yet aware of the problem they probably have. The three plants located in the Northeast that Millennium Power provided outage services for in the three-month period (2020) mentioned above illustrate findings typically identified at other facilities. Here are some of the details from those projects:

The first plant, a 2 × 1 H-class combined cycle began operating in 2017. Delamination was observed on six valves associated with the boilers and steam system at that facility—HP HRSG isolation, HP header isolation (a/k/a blending valve), and HRH (hot reheat) header isolation (for isolating one boiler from the other when necessary). The first type was in the European boiler manufacturer’s scope of supply and sourced from Korea, the mixing valves in the EPC firm’s scope came from another manufacturer.

The 14-in., F91 HP boiler valves were specified for service at 2420 psig/1065F. The type of Stellite hardfacing was not specified. What is known is that no buttering layer was used and that the Plasma Transferred Arc Welding (PTAW) process likely was employed for Stellite attachment. The HP isolation and blending valves are of the parallel-slide gate type and suffered Stellite liberation from both the seat rings and discs.

Note that these valves were manufactured before the EPRI guidelines (sidebar) were published. The EPRI findings identified disbonding concerns beginning at steam temperatures of about 975F, possibly even lower, with shorter expected life as the operating temperature increased.

When restarting the plant after the 2020 spring outage, an HP bypass valve on one of the HRSGs stuck open at 80% of full travel. This particular valve had just been retrofitted with a new magnetite strainer modification and reassembled. Inspection revealed hardened material in the valve, begging the question: Where’s this coming from?

Repair of two valves on the boiler (the stuck-open valve and one additional HP valve), plus inspection and removal of debris from the steam system, were priorities. Some of the liberated material had traveled downstream to the steam turbine. It had piled up against the unit’s protective steam strainers and was removed later, in fall 2020. During both outages, a borescope equipped with a magnet was run up through the steam lines to collect any remaining loose debris.

A specialty engineering firm was engaged to analyze the scrap and make recommendations. There were no unexpected findings. That company also confirmed the importance of a buttering layer. Bezzant recommends a buffer layer of ERNiCr-3 (Inconel Filler Metal 82), or an equivalent PTAW powder, to prevent carbon migration into the Stellite.

The affected valves were disassembled and discs and seat rings cut out. Millennium provided new seat rings and hardfacing for the discs consistent with EPRI recommendations and the company’s experience.

Plant personnel continue to analyze the delamination issue and how to prevent it, with assistance from one of the valve manufacturers. One of the questions they are trying to answer: Is there a temperature at which hardfacing of the type currently used and applied becomes impractical? Another: Is the ramp rate or steam temperature the cause of disbonding?

Steps already taken by the plant include modification of its cold-start procedure (more time) and greater emphasis on the use of sparging steam from an auxiliary boiler to keep the unit warm when offline.

Regular inspections of valves are important to assess their true condition. The plant manager suggested that absent leak-by, your valves likely are fine. But it’s probably a good idea to still select one or two valves at random for a thorough NDE inspection during each hot-gas-path outage. Why only one or two valves? Every time you open a healthy valve you run the risk of compromising its integrity.

If your inspection indicates leak-by, immediate action to correct is recommended.

Millennium Power refurbished four HP valves (isolation and blending) on the affected boilers to return the combined cycle to full power as quickly as possible. Work on the valves was completed in-situ a day ahead of the eight-day schedule. Plant’s plan is to address damage to other valves suffering delamination, as necessary, during future scheduled outages.

In preparation for the fall 2020 outage, Millennium got the repair effort on the two HRH blending valves moving before the outage began by making new seat rings in its shop, Florek touting the company’s ability to reverse engineer and typically make any manufacturer’s valve parts in less time than it would take the vendor of record to supply them.

The first step in the repair process was to remove damaged parts and prep the valves for new parts and hardfacing—something Florek says the company has done at least a couple of dozen times to date. Follow key steps in the montage of photos incorporated into Fig 1. He added that sometimes just the hardfacing is damaged, not the basic part. In such cases it’s sometimes possible to remove the coating and reapply Stellite with the requisite butter layer.

The first step in the repair process was to remove damaged parts and prep the valves for new parts and hardfacing—something Florek says the company has done at least a couple of dozen times to date. Follow key steps in the montage of photos incorporated into Fig 1. He added that sometimes just the hardfacing is damaged, not the basic part. In such cases it’s sometimes possible to remove the coating and reapply Stellite with the requisite butter layer.

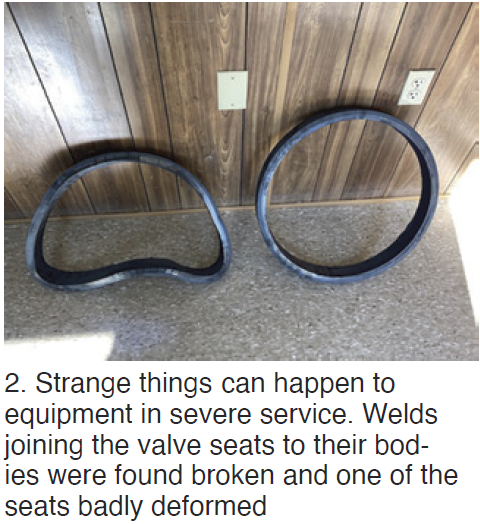

Millennium Power’s field service personnel moved in short order from this project to another in the region where two 24-in. parallel-slide gate valves were refurbished within two weeks. Old seats were removed, new seats manufactured with Stellite overlay and Inconel butter layer, and the valves rebuilt, including new actuators. Original seat welds were found broken; one of the seats was severely deformed (Fig 2).

At the third plant in the Northeast that Millennium serviced within the three-month period noted above, a 24-in. wedge gate valve in the HRH system was scheduled for a stem replacement to mitigate packing wear. A new stem was manufactured in the company’s shop and shipped to the site for installation.

When technicians disassembled the valve, Stellite disbonding was found on the wedge and both seats. The owner approved corrective action the next day and Millennium’s field machining crew arrived onsite four days later to remove both seats while concurrently refurbishing the existing wedge in accordance with EPRI recommendations. Seats were replaced, wedge refurbished, and valve reassembled all within 16 days of project start.

Steam turbine. A case study of damage suffered by a 262-MW D11 steam turbine because of Stellite delamination associated with HRSG steam valves was presented at the 2019 meeting of the Steam Turbine Users Group. The clue that something was amiss: Following a routine valve test, operators recognized that throttle pressure had to be increased by 70 to 80 psig above “normal” to maintain desired output—symptoms consistent with possible steam-path fouling or damage.

After weeks of data monitoring and analysis involving personnel from the owner/operator and OEM, a two-week outage was taken. Delamination of Stellite from the seats of HRSG steam valves was confirmed by investigators and a borescope inspection of the turbine HP inlet revealed significant damage to the first-stage nozzle block and buckets.

Three run-versus-repair options were considered for the steamer: repair now (reliability outage); run at reduced load with no cycling permitted, and repair when new buckets arrive; and run until the major maintenance outage planned for some months ahead.

The OEM’s recommendation was to run the turbine until the planned major and order new buckets and diaphragms for the first four stages of the 262-MW unit; plus, monitor the machine for noticeable changes in operation that would indicate additional damage. Also recommended was that the owner implement a program to inspect and replace similar Stellite-hardfaced valve parts exhibiting delamination.

Be aware that Stellite also has disbonded from the seats of steam-turbine valves; guidelines for their inspection are presented in GE’s TIL-1629R1, “Combined Stop and Control Valve Seat Stellite Liberation,” Dec 31, 2010. Thus, the information provided in this document predates the extensive work done by EPRI, and summarized in the companion article, by five years.

Inspection. Industry experience suggests inspection of large steam valves for delamination and other possible issues during the next hot-gas-path (HGP) or major inspection—especially if this has not been done previously. Wasatch Welding Engineering Services’ Bezzant explains that visual inspection will confirm Stellite liberation, dye penetrant testing will reveal cracking not visible with the naked eye, and a straight-beam ultrasonic examination is necessary to identify disbonding that may be occurring but not found by visual or dye-penetrant examination.

But before opening your valves, he suggests you have a game plan for repair or replacement in case you find damage. Failure to plan ahead could significantly add to your outage schedule.

Here are your options if damage is found, according to Bezzant:

-

- Replace the existing valve with a new one.

- Cut the valve out of the line and send it to the manufacturer or a qualified third-party shop for repair.

- Repair the valve inline.

Owner/operators who have already faced repair/replace decisions suggest that you factor the following facts into your decision:

-

- The lead time for new valves may extend beyond a year.

- Shops capable of doing quality valve work and welding generally have a backlog.

- Quality repairs are difficult to make inline because of preheat and access requirements.

- Field-service organizations with the requisite in-situ valve repair experience are extremely busy.

- There is no industry standard for applying hardfacing, although EPRI’s recommendations for this are supported by those contacted by CCJ ONsite. Manufacturers and repair firms may have other procedures but they should be qualified metallurgically before work begins on your valves. Plus, owner/operators are advised to carefully monitor repair work to the qualified written procedure.

The editors contacted California-based Bay Valve at the suggestion of a user to get an idea of what’s involved in conducting a valve inspection. In two words: A lot. Bay said the company’s standard procedure is to have highly experienced personnel perform visual and dye-penetrant inspections and if cracking or other problem is identified it is referred to plant management, which might decide to expand the scope of the examination.

Preparation for inspecting a 12- to 14-in. HP or 20- to 24-in. HRH valve can take upwards of two days, one of the field supervisors told CCJ ONsite. Actual time depends on the size of the valve, manufacturer, plant constraints, etc. He walked the editors through the rigging and safety measures required to remove a 1-ton handwheel as evidence of some of the difficulties sometimes encountered. Budget another five days to complete the inspection and return the valve to operational condition.

Stellite-free valves. Hardfacing options other than Stellite are used in the industry. They too may have technical challenges and owner/operators should investigate their service histories thoroughly before deciding on what hardfacing material to specify.

ValvTechnologies’ Miller, contacted at the suggestion of an owner/operator with several Stellite-free valves at its plants that have been problem-free for several years save one stem packing leak, discussed the highlights of his company’s IsoTech® design for high-pressure applications.

ValvTechnologies’ parallel-slide gate valves for demanding combined-cycle service rely on the manufacturer’s proprietary RiTech® 31 (80% chromium carbide and 20% nickel/chrome by weight) coating, which is much harder than Stellite 6 (68.5 Rockwell C versus 30 for Alloy 6 at 1000F, a difference that increases with temperature). The coating is applied to critical parts—discs, seats, and guides—in HVOF (high-velocity oxygen fuel) spray booths using a compressive spray technique to achieve high bond strength.

The hard coating on the web guide ensures the discs are kept parallel through the entire valve stroke. As the valve is cycled under differential pressure, the hard surfaces reportedly burnish and polish each other, avoiding the scratching and galling cited by some users not using RiTech 31.

Miller said the company’s new IsoTech hybrid design has a cast A217 C12A short pattern body with welded-on forged end rings (pup pieces) which can be either A 182 F91 or F92 to match the piping-system material. The length of the end rings also can be customized to meet either ASME B16.10 end-to-end dimensions, or be provided longer to allow removal of heat-affected-zone material on valve replacement projects. Expected time for customization to your specific requirements is four weeks or less.

The new valve, characterized by a very low pressure drop, according to Miller, accommodates 12, 14, and 16 in. requirements with the same cast body.