Sulzer’s Rotating Equipment Services unit—formerly Sulzer Turbo Services—offers a wide range of inspection, shop, repair, and manufacturing services for gas and steam turbines, generators, pumps, compressors, and other power and process equipment. The company actively supports the V94/84.2 and V94/84.3A fleets through its participation in user meetings here and internationally. It has major shop facilities worldwide to serve powerplant owner/operators.

Sulzer’s Rotating Equipment Services unit—formerly Sulzer Turbo Services—offers a wide range of inspection, shop, repair, and manufacturing services for gas and steam turbines, generators, pumps, compressors, and other power and process equipment. The company actively supports the V94/84.2 and V94/84.3A fleets through its participation in user meetings here and internationally. It has major shop facilities worldwide to serve powerplant owner/operators.

Not familiar with Sulzer? Tour the company’s website at www.sulzer.com for an overview of shop capabilities pertinent to your equipment—including physical and metallurgical inspections, welding, heat treatment, machining, turbine and compressor coatings, rotor disassembly/reassembly, etc. Sulzer offers field-service (Fig 1) and new-parts manufacturing to complement its repair offerings.

Most of Sulzer’s efforts with regard to V engines focus on the Siemens SGT5/6-2000E and Ansaldo AE94.2 machines. Aftermarket services for about two-thirds of this market segment are “competitive”—that is, not influenced by an OEM’s long-term services agreement. By contrast, Siemens says 80% of the SGT5/6-4000F engines it has supplied are governed by an LTSA.

While Sulzer, like ARNOLD Group and APG, does perform repairs and field services for some 94/84.3A owner/operators, the manufacture of major new parts is not included among its current offerings.

New parts. The company makes the following parts for legacy 94/84.2 engines: compressors; inner casings, mixing chambers, and flame tubes for the combustion section (Fig 2); and Row 3 turbine blades. Plus, for the 94.2 only: combustion-section heat shields and fuel nozzles, as well as turbine blades for Rows 1 and 2 and vanes for Rows 1, 2, and 3.

For 94/84.2 models through Version 7: Combustion-section inner casings, mixing chambers, and flame tubes; turbine vanes for Rows 1 and 2. Additionally, new fuel nozzles are available for 94.2 models through Version 7.

New parts are said to be “ready to drop in,” having the same form, fit, and function as those supplied by the OEMs.

Mods and upgrades for critical 94/84.2 parts are a significant part of Sulzer’s value-add offerings. Some examples follow:

-

- Relocation of the F-ring to mitigate burnout of tile clips by moving the holders to a region of lower temperature, in addition providing easier access to tiles for replacement.

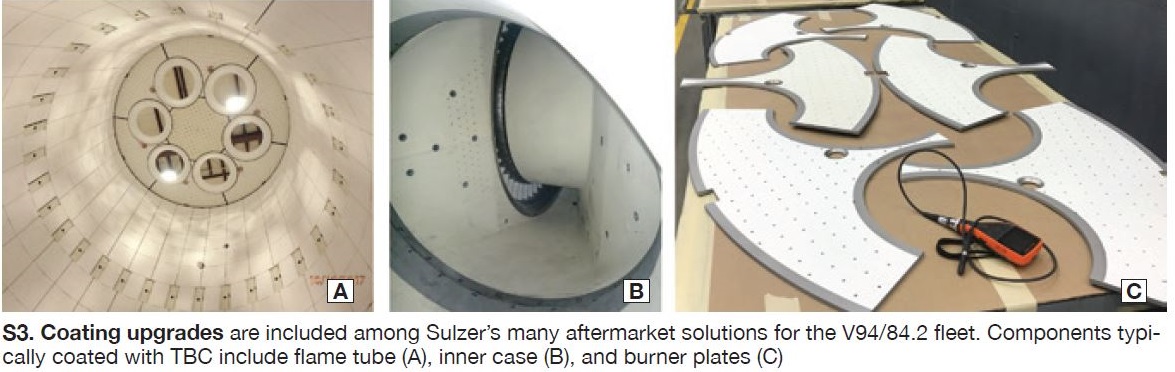

- Coating upgrades for flame tubes (Fig 3). This includes adding thermal barrier coating (TBC) to burner plates, bezel rings, and F-row tile clips; plus, depositing chrome carbide (CrC) on bezel rings and burner plates.

- Flame-tube upgrades include an Inconel overlay for F-rings and Hastelloy-X tile support rings.

- Improved cooling-hole pattern for flame-tube burner plates. Also available are larger plates and a material upgrade to Haynes 230.

- Inner-case upgrades include TBC coating of the hot-gas-path surface and CrC coating of inlet collars.

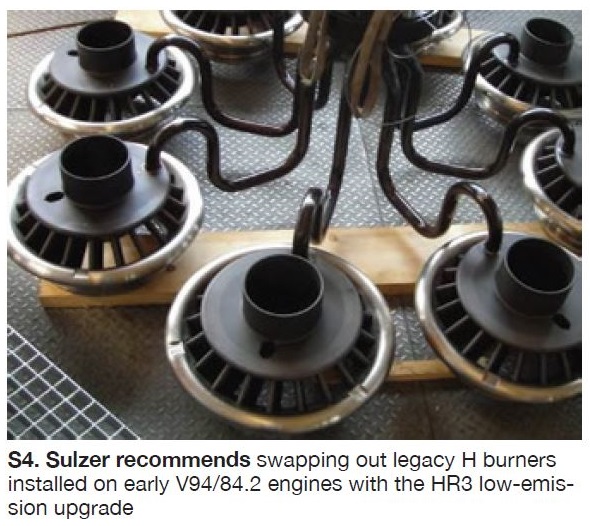

Burners, etc. Sulzer recommends swapping out legacy H burners with the HR3 low-emission design (Fig 4), which is said to offer the following benefits:

-

- More stable combustion, primarily because of better mixing of the fuel gas with combustion air.

- Increased resistance to flame flashback. One reason: The higher velocity of the fuel/air mixture through the HR3’s optimized flow channel reduces the probability of the flame traveling upstream.

- Corrosion-resistant gas supply piping minimizes leakage risk and reduces maintenance.

- Reduced NOx emissions. The better mixing of fuel and air inherent in the HR3 design eliminates flame hot spots (emissions spikes) associated with the H burner.

Sulzer also actively promotes its E-UP program for the 94/84.2 fleet, which promises users a 5-MW increase in power output and a 0.8% efficiency improvement for retrofitting turbine Rows 1 and 2 blades and vanes with airfoils of its design. All incorporate what the company believes is an improved nickel-base superalloy (Rene 80), TBC coating system, and more efficient airfoil design.

The specific coating system selected depends on an engine’s operating conditions. Generally speaking, MCrAlY is used on the external surfaces of Row 1 and 2 airfoils because of its superior oxidation and corrosion resistance in both base- and peak-load applications. Use of TBC is optional where necessary to reduce metal temperatures and thermal gradients for improved protection against creep and fatigue. Internal surfaces have an aluminum diffusion coating to help prevent intergranular attack.

In addition, R1 vanes feature internal impingement cooling, re-staggered and optimized airfoil design, integrated cover plate with impingement cooling, and cut-back trailing edge. Highlights of the R2 vane design include tilted and optimized airfoil design, serpentine internal cooling geometry, and throttle sleeve to control the mass flow of cooling air.

For R1 turbine blades, enhancements include: cut-back trailing-edge design adopted from the 94/84.3A blade, serpentine internal cooling geometry, and squeeler tip.

The enhancements cited above are said to allow Sulzer’s Row 1 and 2 turbine blades and vanes to operate reliably in engines with turbine inlet temperatures of up to 1080C (1976F).