Editor’s note: Given the existence of several standards for the classification of gas-turbine inlet filters, which can cause confusion in the minds of at least some owner/operators, Donaldson has developed a user-friendly filter rating system that measures efficiency and two other properties crucial to power output and cost control. The company’s goal is to build a consensus to support adoption of this three-part rating system industry-wide. The article that follows, written by Michael Roesner, who manages the aftermarket business for Donaldson Company Inc’s Gas Turbine Systems Div, provides the details.

Gas turbines are designed to mix dry, clean air with fuel to produce energy. Because intake air quality is critical, effective inlet design and air filtration are required for top performance. Based on EPA data, approximately 1300 pounds of particulate matter could enter an F-class gas turbine inlet house and filters in a typical year of operation. Airborne dirt and contaminants can cause power loss, drive up fuel costs, and damage vital components.

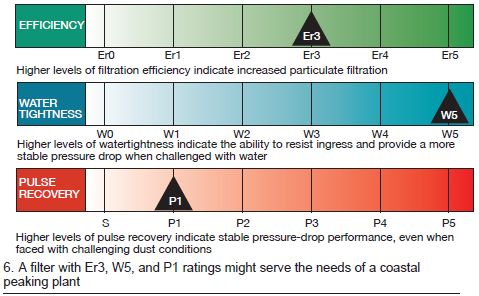

Three performance factors important to selection of the proper filter for your plant are efficiency, water-tightness, and, in pulse-cleanable applications, pulse recovery rate. Think of them as the key filtration “pillars” that support optimal gas-turbine operation. In most cases, all three performance factors are important, but their ranking may vary depending on the local environment and operating conditions.

The Three Pillars can be described as follows:

Efficiency. The proportion of particulates entrained in the inlet air and captured by the filter is the most widely recognized performance metric. Because higher-efficiency filters have associated costs, operators need to determine an efficiency rating that delivers the best return on investment (ROI).

Water-tightness. In humid or ocean-front locations, resistance to moisture becomes a high priority. Salts and other dissolved solids carried by water can be highly corrosive and oftentimes more detrimental than airborne contaminants.

Pulse recovery rate. How readily filters regain peak performance after pulsing is a third key concern. High pulse recovery rises to top priority in desert or arctic environments, where there is either continual exposure to dust, snow, and ice buildup, or potentially sudden episodes of heavy loading.

Careful evaluation is necessary on a case-by-case basis to determine the ranking of these factors for a local situation and operating budget. Identifying priorities enables the most appropriate inlet design and filter combination to be incorporated into your gas turbine system.

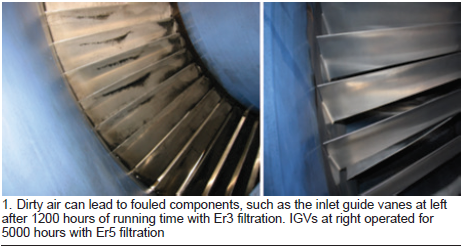

Balancing ratings with cost. Higher filtration efficiency produces cleaner air, which translates into more efficient combustion, sustained power output, and longer-lasting turbines. Dirty air introduces particles that can foul turbine components, decrease compression efficiency, and adversely affect compressor health, as shown in Fig 1.

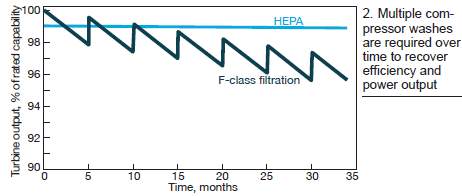

Compressor water washing can be used to regain power output lost to fouling; however, an overall decrease in efficiency may occur after repeated washings. Fig 2 compares the performance of a GT equipped with a typical F-class filter, after multiple washings, to a similar engine with high-efficiency particulate air (HEPA) filters that did not require online washing.

The downward-sloped lines for the standard filter represent output decreases caused by fouling, followed by upward swings from washing. Note that after multiple washings, output of the engine with a standard F-class filter is less than that of a HEPA filter with no online washing.

A HEPA filter can reduce the need for compressor washing and maintain higher turbine efficiency. This also reduces “soft costs” related to maintenance and equipment downtime. With turbine availability often a key factor in evaluating the financial bottom line, outage costs can be significant.

Other factors affecting filter efficiency include airflow and pressure drop. Reductions in inlet pressure from blockages or poorly sized filter elements can compromise turbine output. If a filter operates at a flow rate that exceeds design specifications, the resulting pressure drop can adversely impact system performance. Pressure drop will often increase as the filter loads.

However, there are trade-offs to consider, and a balance must be achieved. Because the increased pressure drop of a higher-efficiency filter can still support long-term gains, system owners and operators should work closely with their filter supplier to determine optimal ratings and filter characteristics.

Various efficiency rating systems have been developed (Sidebar 1). Donaldson has designed an efficiency tool that combines the different approaches into one, easy-to-use efficiency scale, ranging from Er0 to Er5—the higher the number the greater the degree of particulate capture.

1. Efficiency rating and classification methods

Filter efficiency indicates how well a filter performs by comparing the concentration of particles upstream and downstream of the filter. Removal efficiency typically is expressed as a percentage of capture. However, filtration-efficiency classifications have varied.

In the US, filters historically have been classified with a Minimum Efficiency Reporting Value (MERV) rating, which was developed by the American Society of Heating, Refrigeration and Air-Conditioning Engineers (ASHRAE). MERV ratings range from 1 to 16, with a higher score indicating better performance. In Europe, two standards have been used: European Normative (EN) 779 and EN 1822. EN 779 standards include ratings of G1-G4, M5-M6, and F7-F9, which generally encompass the same range of efficiencies as MERV ratings 1-15.

The terms “efficient particulate air” (EPA) and “high-efficiency particulate air” (HEPA) are the most familiar measures regarding premium levels of filtration efficiency. According to the EN 1822 standards, HEPA is defined as a minimum of 99.5% removal of the most penetrating particle size. EN 1822 filters have ratings of E10-E12, generally corresponding to EPA and HEPA filtration levels.

More recently, a new standard, ISO 16890 (CCJ No. 57, 2Q/2018, p 88), has been introduced worldwide to unify how filters are tested and rated. The methodology focuses more on particulate matter (PM) classes. The ISO 16890 test protocol challenges filters with particulates in a broad range of diameter sizes, then measures average capture in three specific ranges: PM1, PM2.5, and PM10.

The complex nature of multiple testing standards motivated Donaldson to design a tool that combines these testing standards into one, easy-to-use efficiency scale, ranging from Er0 to Er5 (refer to Fig 6 in text), and to develop ratings for two other performance factors equally important in filter performance—water-tightness (W0-W5) and pulse recovery (PS to P5)—for a more accurate filter profile.

Water-tightness. Much like dust that escapes an inefficient filtration system, water also can impact turbine performance. Moisture that enters the airstream can introduce dissolved salts and other solids. Compounds such as iron oxides, chlorides, and other contaminants can cause corrosion over time. Turbine blades then have to be repaired and re-balanced—another expensive maintenance task and contributor to extended downtime.

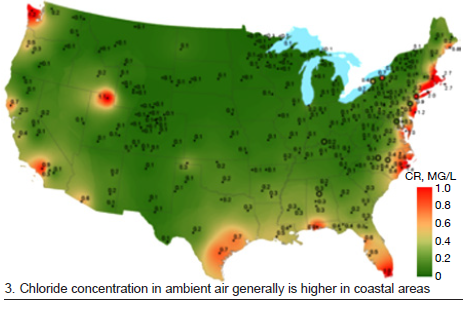

Water-tightness is particularly important in coastal areas, with salt-laden ocean moisture subjecting equipment to accelerated corrosion. Consequently, protection from saltwater represents a key factor affecting the life of gas turbines. OEMs usually recommend that less than 0.01 ppm of salt enter their gas turbines.

In coastal environments, airborne salt can easily range from 0.05 to 0.5 ppm on a typical day. According to data compiled by the National Atmospheric Deposition Program, chloride concentrations in the atmosphere along coastal areas are sometimes more than 10 times the concentrations of inland areas (Fig 3).

Petrochemical environments also present challenges, as hydrocarbons can enter the airstream without adequate water-tightness. These products can place gummy deposits on blades and adversely affect performance.

Water-tightness should be simple for an operator to evaluate. Ask your filter supplier to provide an independent laboratory test report verifying that a particular filter option is watertight and if not, how it will perform under wet conditions.

Donaldson developed a new methodology for testing filters in a controlled environment to determine how much, if any, water can pass through a filter. The test directs a 60-liter/hr water spray at the filter over an 8-hr period. The filter pressure drop and volume of water passing through the filter are recorded.

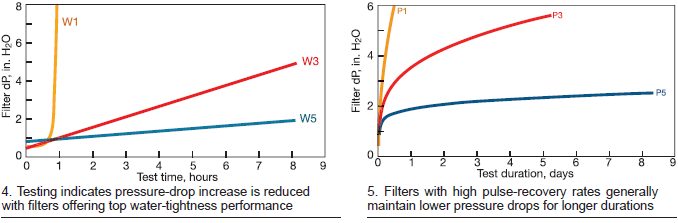

Based on this information, the company rates its gas-turbine filters on a scale of W0 to W5, with higher values indicating greater water-tightness. A filter rated at W0 would not be able to withstand any moisture, while a W5 filter could survive the test with at least 99.5% water stoppage and no more than a 2-in.-H2O increase in pressure drop. Donaldson has tested and rated its most commonly used GT air filters on this scale of water-tightness. Fig 4 shows how higher rated filters reduce the increase in pressure drop over time.

Recovery rate for pulse cleaning. When dust builds up on filters, the resulting drop in airflow compromises power output. Inlet filtration designs include either static or self-cleaning (pulse) systems. Pulse recovery rate measures how often filters in self-cleaning systems can stand up to pulse cleaning and how much pressure drop can be recovered each time (Fig 5).

In pulse-designed inlet houses, filters are cleaned automatically with compressed-air “pulses” from the clean-air side of the filter. This dislodges dirt particles and debris from the surface loading media of the dirty filter, thereby reducing the cost of operation by minimizing pressure drop, extending filter life, and preventing shutdowns because of filter fouling. Self-cleaning systems operate with the GT online.

The recovery rate is the rate at which the filter comes back to a “like-new” condition and stabilizes the pressure drop to allow continuous operation. The higher the pulse recovery rate, the more cleanable a filter is. Recovery rates in pulsed systems are largely dependent on the environment and media type in the filter: surface-loading or depth-loading.

The latter have layers that trap progressively smaller particles on each layer. While they retain a wide range of particle sizes, they cannot be cleaned easily. Surface-loading filters, on the other hand, trap all particles on a single media layer, and form a slight “dust cake” that is easily removed, extending filter life.

As with efficiency and water-tightness, pulse recovery can be rated using laboratory test data. Donaldson developed a process for measuring this characteristic. Exposing filters to a long duration of simulated sandstorm conditions, filter pressure drop and efficiency are measured to arrive at pulse recovery ratings.

On the Donaldson scale (Fig 6), a static (S) filter cannot be pulse-cleaned without damaging it. The ratings from P1 to P5 in the figure indicate the level of pulse recovery. There are a variety of performance factors with static filters and Donaldson is developing an independent rating system for these applications.

If your filter housing does not have a pulse system, static filtration solutions are most appropriate. A typical static solution utilizes depth-loading filter media and focuses on maximizing filter life by balancing pressure drop and dust holding capacity.

However, the advantages of a pulsable filter system can be illustrated by way of the following simplified example: If 10 grams of particles are captured daily by a filter, in 100 days, a total of 1000 grams would be collected. The buildup of particles would also result in a pressure drop in the system. If the pressure drop were deemed to be approaching allowable limits, the filter would either need to be replaced or cleaned. A surface-loading filter could be cleaned during operation, while a depth-loading filter would have to be replaced.

Pulsable systems are often most valuable in areas with significant dust, snow, and potential ice build-up. In these conditions, the longevity benefits of the filtration system can far outweigh the additional cost of a pulse cleaning system. In areas less prone to dust, snow, and ice, pulsable systems may not be as cost-effective.

There are considerable advantages to operating a pulse-cleaned system. Much like an automobile windshield wiper, pulse-cleaning may be mainly a contingency for adverse weather events. But when a demand occurs, and a power interruption could be catastrophic, the value of pulse-cleaning becomes clear.

A fully functional system—including elements compatible with pulse-cleaning—can provide operators peace of mind. If you inherited an existing system with pulse-cleaning, in most cases the advantages of maintaining and equipping it with a pulsing-compatible filter outweigh the costs of an unplanned outage.

The relationship of recovery rate and pressure drop can be seen in Fig 5. This graph illustrates how long three filters with various pulse-recovery rates maintained acceptable filter pressure drop over time in a simulated dust-challenged environment. Generally, filters with higher recovery rates maintained lower pressure drops for longer durations.

Operation of pulse-cleaning systems also needs proper consideration. Systems generally are operated by one of three methods: manual, automated based on pressure drop, or automated based on time intervals. Regardless of whether manual or automated methods are used, cleaning needs to occur before fouling reaches a problematic state. For example, if a cleaning is not triggered by an appropriate time interval, fouling can reach the point of causing significant operational problems.

As it is with any O&M function, neglect increases the risk of failure.

In some instances, the pulse system will only be needed to prevent catastrophic fouling. In periods of ice, snow, extreme frosting, and sandstorms, the pulse system can actually keep the turbine running by using the pulse system as a preventive measure.

Evaluate your needs. Environmental conditions largely drive decisions on inlet system design and filters. The Three Pillars—efficiency, water-tightness, and pulse recovery rate—typically do not stand alone, but require integration. Identifying the ideal balance and combination for your gas turbine should factor in potential downtime costs and long-term ROI.

In evaluating ROI, numerous factors can impact filtration costs. Each operator’s scenario must be evaluated: Not everyone’s ROI will be the same. For example, in evaluating filtration efficiency, a higher efficiency rating cannot always be justified. Only if increased output and operational savings offset the cost of a slightly increased pressure drop can a financial ROI be realized.

Lower efficiency can sometimes actually be more cost-effective in the long run. Similarly, water-tightness might outweigh efficiency in coastal areas, but not in arid locations, where exposure to corrosive ocean air is unlikely.

Every situation is different, and thorough review of operator needs is necessary to identify the optimum filter design. Economic impacts, not just technical factors, require consideration. The bottom line is to evaluate which factors are most important to meet the operator’s needs.

As an example of how efficiency, water-tightness, and pulse recovery should be integrated in filter selection, consider a peaking plant in a coastal environment. Because the plant only operates for short durations, a high-efficiency filter may be difficult to justify economically. The payback for the additional cost of high-efficiency filters would likely be much longer than for that of a continuously running plant.

Because the plant is in a coastal area, water-tightness may be important, but pulse recovery may be less critical if dust exposure is minimal. A filter with Er3, W5, and P1 ratings in efficiency, water-tightness, and pulse recovery, respectively, might serve the needs of such a situation.

Finally, Sidebar 2 offers examples of evaluations at two plants that suggested changing the existing filters for a more-effective and economic alternative.

2. How to select the optimal air filter for your plant

Donaldson’s inlet air-filter rating system was developed to help plants convert to the optimal filtration solution for their unique operating and environmental conditions. If plant conditions change, the appropriate filtration option can be identified based on efficiency, water-tightness, and pulse recovery—the three attributes that differ most from one filter to another and, in combination, also drive operating cost.

Using a baseline profile of the current filter, the owner can select replacement filters with stronger ratings on the properties that matter most under the new conditions. An Er/W/P profile provides an apples-to-apples comparison and enables a better match. Donaldson uses standardized testing to determine the Er/W/P on a 0 to 5-point scale, as described in the text, for both the current filter as well as the proposed solution.

Below are two hypothetical case examples of a beneficial filter conversion using Er/W/P ratings:

Case 1: Environmental issue. A plant in an agricultural region is coping with a dusty harvest season by using a pre-filter wrap on a depth-loading filter. The pre-filter and filter begin to quickly load and require frequent replacement. The owner discovers a nearby rock quarry has reopened, compounding the dust problem.

Donaldson removes and tests the plant’s current filter, discovering it has medium-high capture efficiency (Er3), moderate water-tightness (W2), and weak pulsability (P1). The trouble becomes apparent: The existing filter’s limited pulse recovery rate (P1) cannot keep pace with the high dust load.

Using this comparative information, Donaldson recommends an Er3/W1/P5 replacement. No water-tightness is required in the filter, but it has to deliver the highest possible pulse recovery rate (P5) to shed the heavy dust load. With this change, the plant runs continuously through high dust occurrences and projects a rapid ROI.

Case 2: Operational change. A peaking plant running 1500 hours annually on demand needs to convert to a baseload system that can run 8000 hours. Since downtime becomes a new concern, water washing is no longer an option to optimize compressor efficiency. Compressor health and stable power output become the plant’s main management concerns—and the answer is a different kind of inlet air filter.

In a consultation, Donaldson removes and tests the original synthetic filter and finds that it provides medium-high efficiency (Er3), minimal water-tightness (W1), and maximum pulsability (P5). It recommends switching to a filter rated Er5/W5/P1—providing greater efficiency and water-tightness, with less emphasis on pulsability. The recommendation enables the plant to minimize downtime and maximize power output.