CPV Towantic Energy Center

Owned by Competitive Power Ventures

Operated by NAES Corp

805-MW, gas-fired 2 × 1 7HA.01-powered combined cycle is equipped with DLN2.6+ AFS combustion systems, located in Oxford, Conn.

Plant manager: Larry Hawk

Reducing nuisance alarms

Challenge. Since commissioning, CPV Towantic personnel have identified an abundance of nuisance alarms, as well as other alarms whose priorities were improperly identified.

Primary concern was that there were several Priority-1 alarms that weren’t as serious to Towantic operation as they were indicating. There also were alarms with priority locations that were easy to miss on the busy alarm screen and needed some sort of audible sound that wasn’t available. This resulted in an increase of alarms, making it difficult to identify when action was needed, while nuisance alarms may have been given more attention.

Solution. First step in resolving the issue was to export all alarm-system points to Excel and begin the process of identification and remediation. There were 9490 points that had to be sorted through, verified, and prioritized.

Management divided the project among the plant’s five control room operators with help from the lead CRO in reviewing the points and making changes/comments on the revised priority levels.

On the first run-through, the CROs identified 706 alarms that would benefit by changing their priority levels to reduce the number of nuisance alarms, and by making some low-priority alarms a higher priority. There was a large number of alarms that the CROs wanted audible alarms for, but they didn’t necessarily meet the plant’s Priority-1 definition.

Solution was to create a secondary audible sound for Priority-2 alarms, different from the Priority-1 tone, to help get the attention of operators and enable them respond appropriately without causing a nuisance.

Having a second audible alarm, Towantic was able to reduce the number of alarms earmarked for a priority change to 196. The operations manager and plant engineer compiled the final changes and during the spring 2022 outage, staff programmed a Priority-2 audible and changed the priority of 196 alarms.

Screen shots of an alarm workbook page and an alarm screen were provided with the entry but their resolutions in print were too poor for publication.

Results. Though alarms still are received in the control room, their organization, frequency, and urgency are better defined and appropriate for helping the CROs respond effectively. The changes also give the CROs confidence that they can take action and understand the true plant condition when issues arise—this while avoiding the stress of a nuisance alarm taking them away from other important duties.

While the bulk of the proposed changes have been made, plant personnel continue their remediation efforts in reducing nuisance alarms and making the alarm system more effective.

Project participants:

Ryan Earnheart, lead control room operator

Stosh Kozloski, control room operator

James Murray, control room operator

Michael Gilbert, control room operator

Jason Johnson, control room operator

Brandon Martin, control room operator

In-house fabrication of critical turbine transmitter enclosures

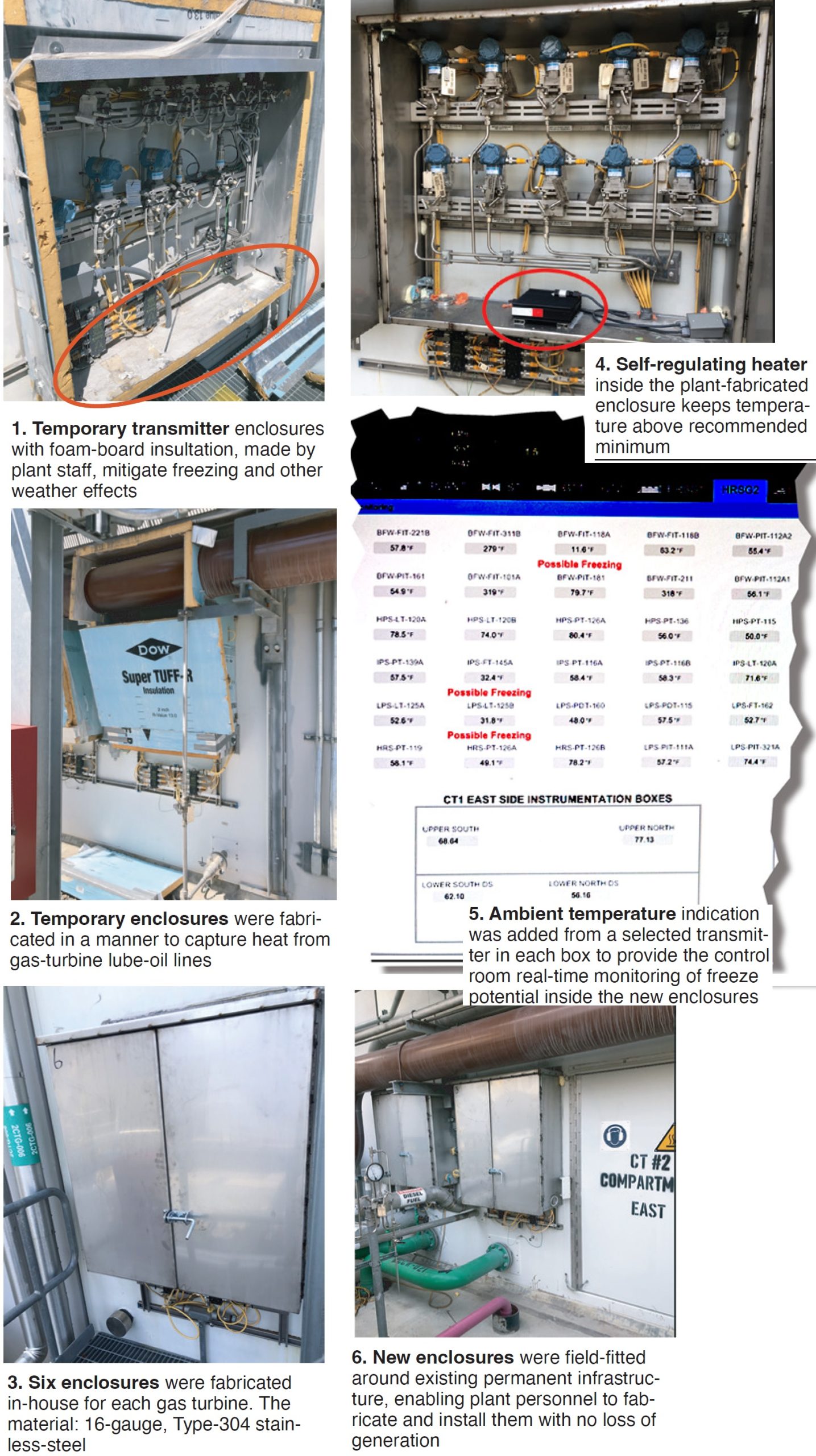

Challenge. The OEM-supplied turbine enclosures at this outdoor facility left critical gas-turbine transmitters exposed to ambient conditions without heat tracing, weather guarding, or insulation.

Towantic experienced trips attributed to instrumentation freeze-up and quickly put in place a foam-board insulation “stop gap” to help protect the transmitters (Fig 1). Temporary heat tracing also was installed as part of this impromptu freeze-protection effort. Insulation and heat tracing addressed most concerns, but equipment still was susceptible to the colder “polar vortex” days that the site might experience.

Several other improvements also were proposed and implemented to mitigate the effects of cold weather—such as capturing heat radiated from gas-turbine lube-oil lines (Fig 2).

Solution. Plant personnel wanted a more-permanent freeze-protection solution and invited several vendors to walk down the gas-turbine enclosures and share their expertise. But staff soon realized that an ideal solution was not available on the market, or at least for reasonable cost. Internal discussions resulted in a custom-designed, fabricated, and installed set of enclosures proposed by Plant Mechanic Brian Kennedy.

Having previously completed similar projects, Kennedy explained his design and provided a list of materials and tools needed to complete the project. The three-sided enclosures installed are of a shelled design consisting of 16-gauge, Type-304 stainless-steel inner and outer shell walls with a high-temperature polyisocyanurate insulation embedded between them (Fig 3).

The stainless-steel walls were bent using purchased tooling and insulation was placed between the walls and stitch-welded along the seam to create an effective weather-tight barrier. The new enclosures also feature weather-sealed double doors of the same design for access to the transmitters and self-regulated heaters (Fig 4) specified and installed by IC&E Technician Matthew Trafficante. This design also allowed field fabrication for bulkhead penetrations and installation to be done without interrupting generation. The enclosures require no painting or maintenance.

Finally, the ambient indications available on the transmitters protected by these new enclosures were added to the DCS screens in the control room, thereby allowing remote monitoring (Fig 5). An alarm alerts the CRO when further attention is needed—such as when a heater fails.

Results. Towantic has eliminated, or severely reduced, the possibility of lost generation and equipment damage caused by transmitter freeze-up and other weather-related complications. Enclosures were installed for the cost of materials only (Fig 6) while the units were online (no downtime required). This amounts to a six-figure saving compared to the alternative of contracting out the project to a third party.

Project participants:

Brian Kennedy, plant mechanic

Matthew Traficante, IC&E technician

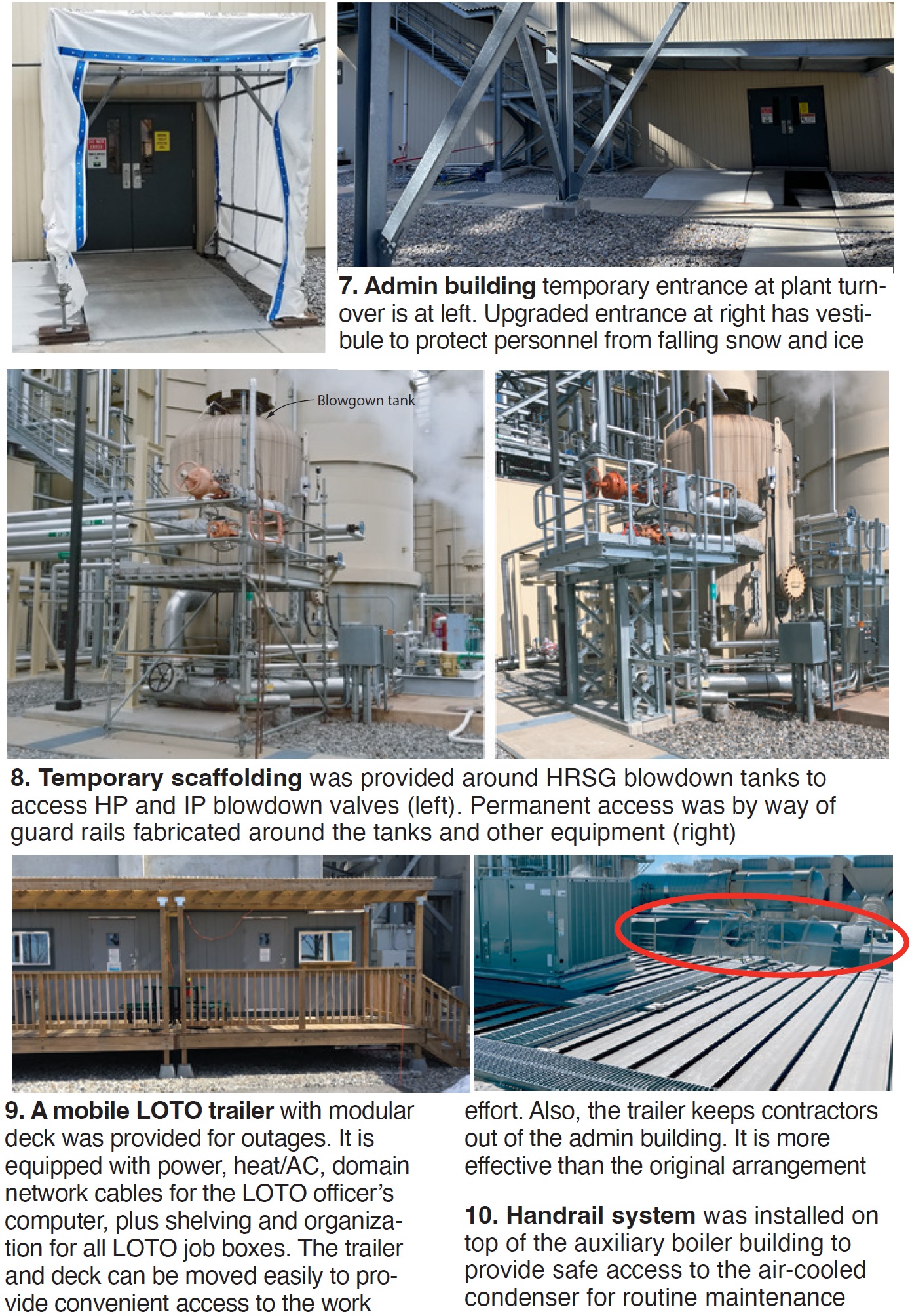

Capital improvements to plant infrastructure focus on personnel safety

Challenge. Final plant design/construction upon turnover to the Towantic O&M team lacked capital infrastructure platforms, ladders, enclosures, etc. This required the erection of scaffolding to serve as “temporary” enclosures and platforms to perform routine plant operations.

While not ideal with respect to performance and safety, scaffolding also is costly to retain onsite and maintain its certification. Plant personnel have been very careful working around the temporary scaffolding and there have been no injuries or OSHA recordables since commissioning. However, the possibility remains.

Solution. Plant management and Towantic’s owners developed a prioritized capital improvements list to address the lack of infrastructure and the safety/operational concerns it creates. Owners have set aside money for capital investments every year since commissioning to complete permanent projects for safer and more reliable operations. Management works through the agreed upon capital-improvements list, completing projects through a prioritized and fiscally responsible program annually.

This list includes 27 identified areas that could benefit from capital improvements; the list is a living document undergoing continual updating both by the owners and plant management. To date, a dozen of the 27 areas identified for capital investments have been addressed.

Thumbnails of several projects completed through calendar year 2022 are described in Figs 7-12.

Results. CPV Towantic has eliminated safety concerns through engineering and installation of permanent structures, while simultaneously improving O&M reliability. This initiative continues as areas recommended for improvement are identified.

Project participants:

All plant O&M personnel