Turbine Tip No. 17 from the PAL solutions library applies to most models of legacy GE gas turbines.

Fast starting was a feature offered on some General Electric Package Power Plants (PPP) as a response to electric-utility concerns following the Great Northeast Blackout of 1965. Power companies in the US and Canada became aware very quickly that they did not have adequate “emergency and peaking power” that could react urgently to power demands—particularly in blackout situations.

The apparent need was in situations where power was needed in a matter of minutes, not hours, as with fossil-fuel steam turbine/generators.

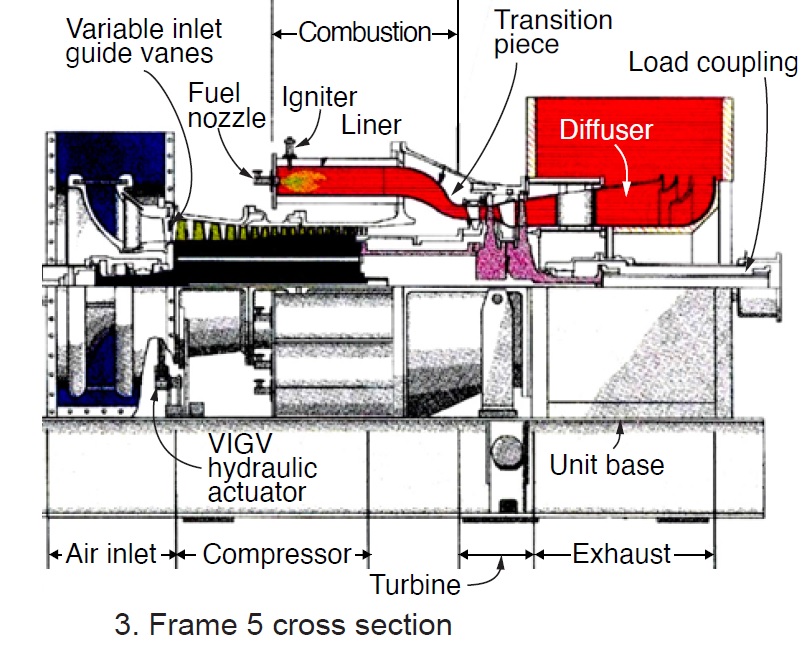

Normal starts of units with “black-start capability” typically took from five to six minutes to go from signal initiation to 100% speed. This was called full-speed/no-load (FSNL), which was 5100 rpm for Frame 5Ps and 6Bs and 3600 for Frames 7B-7EA. Interestingly, the first Frame 7, rated a nominal 40-50 MW and installed by Long Island Lighting Co in 1970, only came with an electric-motor starting device.

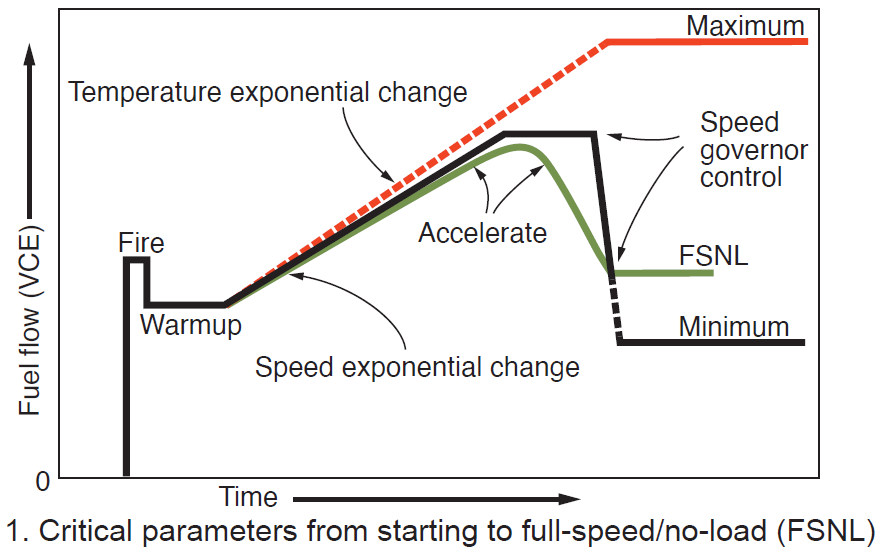

Gas turbines normally had specified warmup periods for “heat soaking” of internal turbine parts. The starting and loading sequences were controlled with reliability and long-term life in mind. Typical normal starts from 0 rpm up to FSNL consisted of the following steps (Fig 1):

- Starting and warmup of the diesel engine, if applicable—30 seconds.

- Firing and warmup of the turbine at 20% speed—60 seconds after sensing flame in the combustors.

- Acceleration to FSNL:

- Shaft exponential—a set rate in Speedtronic™ controls.

- Rate-of-change of speed—0.5% increase in speed per second.

- Rate of increase in exhaust temperature—5 deg F/sec.

- Fuel limit during acceleration—VCE is set in the Speedtronic controls.

Typical loading rates to baseload were the following:

- Operation at 100% speed (FSNL)—minimal time before synchronizing with the grid.

- Normal loading to baseload—increasing from 0 MW to baseload in 90 seconds.

The times allowed were established by the OEM to safely bring the gas turbine up to operating speed. Normal starts took from five to six minutes. Fast starts (warmups eliminated) took only three and a half minutes.

Synchronizing to the grid and slow loading should be the norm to extend the lives of internal parts. The times noted above were based on turbine inlet (a/k/a firing) temperature, which is calculated from measuring these two variables: turbine exhaust temperature (TXA) and compressor discharge pressure (CDP).

The actual output in megawatts depends on one or more of the following variables, among others:

- Ambient temperature at the compressor inlet.

- Inlet-air pressure drop across the filters.

- Atmospheric pressure.

- Compressor discharge pressure.

Gas turbines can suffer significant life penalty if fast starts are initiated too often. A starting regimen that eliminates warmup periods is permitted, but discouraged, particularly when starting from a cold, standby condition. It is akin to loading the unit to “peak,” if allowed at all, because “overfiring” the turbine reduces parts life.

Of most interest in Fig 1 is the center of the graph. There is a normal starting rate built into the Speedtronic control system. If the rate of rise in exhaust temperature is faster than 5 deg F/sec, fuel flow (VCE) will take command. If the rate of acceleration (speed exponential change) exceeds 1%/sec, this subsystem takes control of fuel flow. All three rates are built into the control system and have and established relationship to protect the turbine.

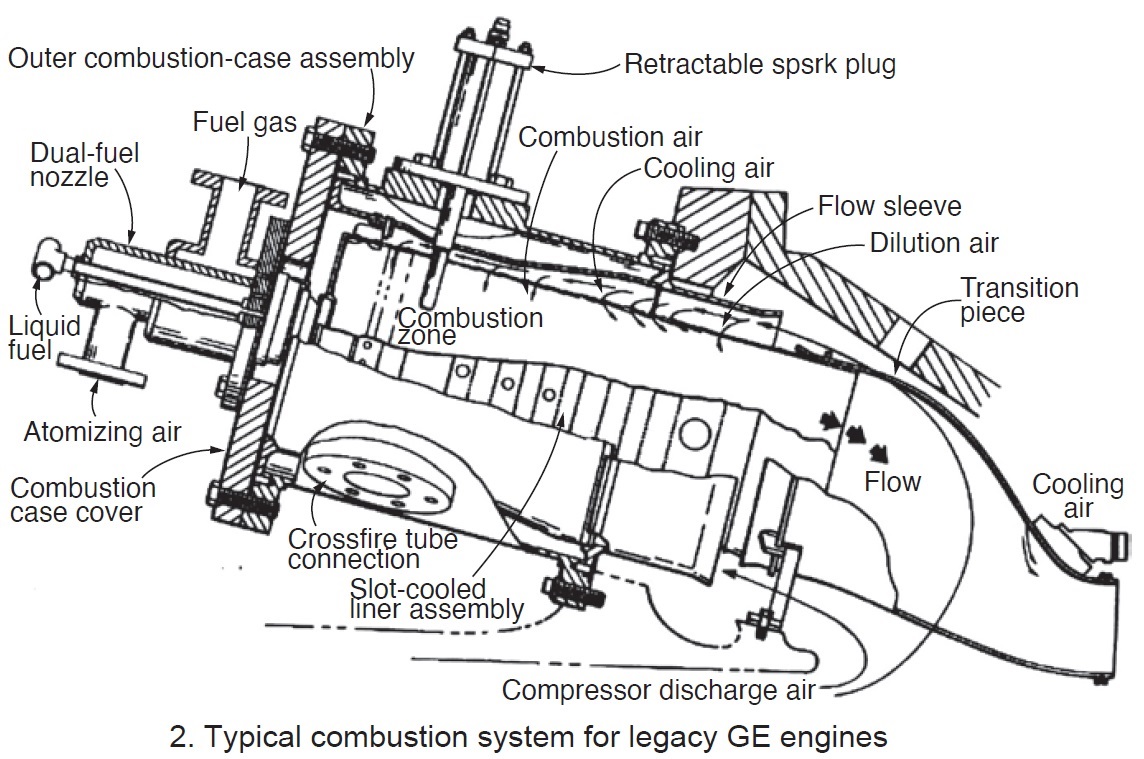

The lives of combustion-section parts (Fig 2) decrease significantly if the turbine components do not have a reasonable amount of time to “heat soak.” This is particularly true of combustion liners, crossfire tubes, and transition pieces for each of the 10 combustion chambers on the GE Frame 5P, 6B, and 7B-EA engines of interest here.

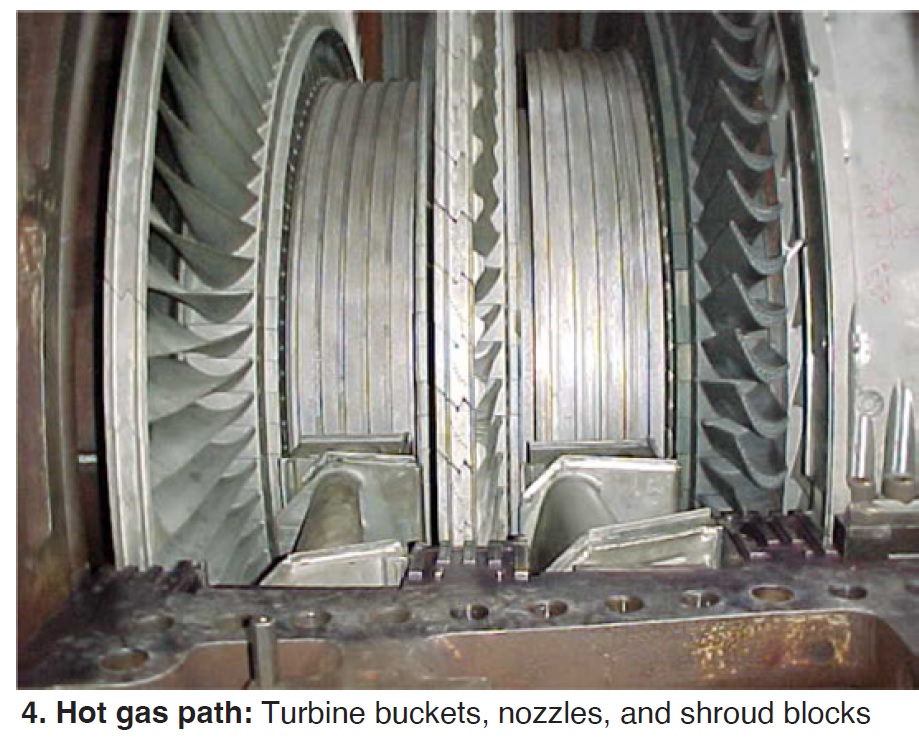

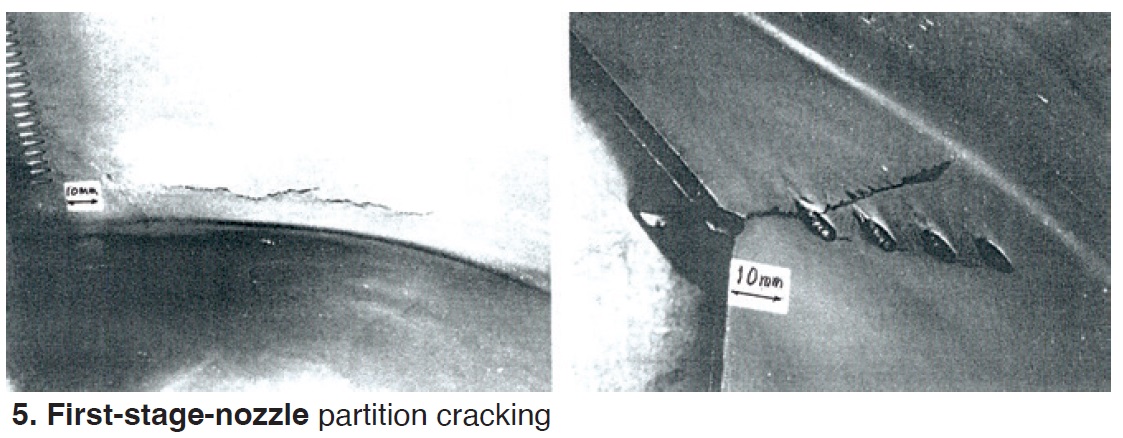

The hot-gas-path (HGP) parts shown in Figs 3-5 will be prone to cracking and distortion if fast starts are used too often. This is particularly true of the first-stage turbine-nozzle partitions and turbine buckets. The OEM says rapid heating without the recommended warmup period may shorten the lives of internal parts by a factor of five.

This means HGP inspection inspections will be required more frequently and the cost of repairs or replacement parts will be significant. Particularly vulnerable to cracking are the trailing edges and sidewalls of the nozzle partitions. Recall that the most expensive parts in the turbine are in the HGP because they are made with the most sophisticated materials and require precise heat treatment.

In Fig 5, consider that if the nozzle partition cracks propagate to connect in a way that material liberation could occur, repairs or a replacement nozzle is highly recommended. You don’t want liberated material traveling downstream and damaging rotating or stationary components in the flow path.

In Fig 5, consider that if the nozzle partition cracks propagate to connect in a way that material liberation could occur, repairs or a replacement nozzle is highly recommended. You don’t want liberated material traveling downstream and damaging rotating or stationary components in the flow path.

In conclusion, keep in mind that while fast starts are permitted by the OEM for most package power plants, internal components may suffer cracking and degradation, and the practice should be avoided except for true emergency situations.

End note: Dave Lucier, author of the Turbine Tip series that has appeared regularly in CCJ for the last five years, has closed the doors of his Pond and Lucier LLC shop in Amsterdam, NY. Dave’s career in gas turbine services and training began at GE in 1968. In the 55 years since he has worked in 20 countries, 31 states, Puerto Rico, and the Virgin Islands. There isn’t much he hasn’t experienced concerning legacy GE frames and their control systems going back to pre-Speedtronic days.

Although the shop doors are closed, Dave still has some premium parts available for sale—typically pre-1980 fuel pumps, flow dividers, fuel regulators, and unused Speedtronic Mark II circuit boards. Contact him at dlucier@pondlucier.com if interested.

Finally, Dave will continue to help clients and consult in his areas of expertise without getting his fingernails dirty. Contact him by email.