AES Levant Power Plant

Owned by AES Corp, Mitsui, and Neberas Power

Operated by AES Levant Holdings BV Jordan

250 MW, tri-fuel peaking facility consisting of 16 Wärtsilä 18V50 diesel/generators located in Al Manakher, Jordan

Plant manager: Feras Hammad

Protect waste-gate actuator from heat damage

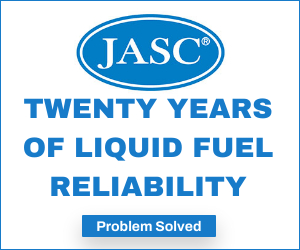

Challenge. Function of the waste gate is to control the air/fuel ratio when burning natural gas in the peaking plant’s diesel engines. Problem faced by plant staff: The waste-gate actuator (Fig 1) was prone to a controls failure caused by heat coming from a damaged bellows near where the waste gate is located.

Solution. Insulate the waste-gate actuator from the heat coming from the engine’s exhaust-gas system. Do this by designing and fabricating an insulation jacket designed for use at up to 500F. Final step: Cover the waste-gate device with the fabricated jacket (Fig 2).

Results. Project goals of reducing maintenance man-hours and cost, and improving plant availability and reliability, were achieved. The saving during 2022 was about $28,000.

Project participants:

Amer Manaseer

Mohammad Abu Hayja

Isolate SCR control-air system to prevent a plant trip

Challenge. The 100-psig control air system for Levant’s SCR is equipped with several leak-prone flexible rubber hoses. Should a leak occur, the plant could be at risk of tripping offline because of low control-air pressure.

Solution. Several possible solutions were evaluated for the effort involved in their implementation and effectiveness. The alternative selected: Install a shutoff valve with a pressure switch in the compressed-air pipe feeding the SCR system to cutoff air at the SCR if leaks occur in the system. Keep a sufficient amount of control air flowing to keep the plant running smoothly until permanent repairs can be made.

Results. Saving in 2022 was estimated at $16,000, more than twice the $7700 cost of the improvement.

Project participants:

Mazen Alamro

Mohammad Jaradat

Ibrahim Arori

Ahmad Bani Hani

No instructions for servicing fuel-oil injectors, no problem

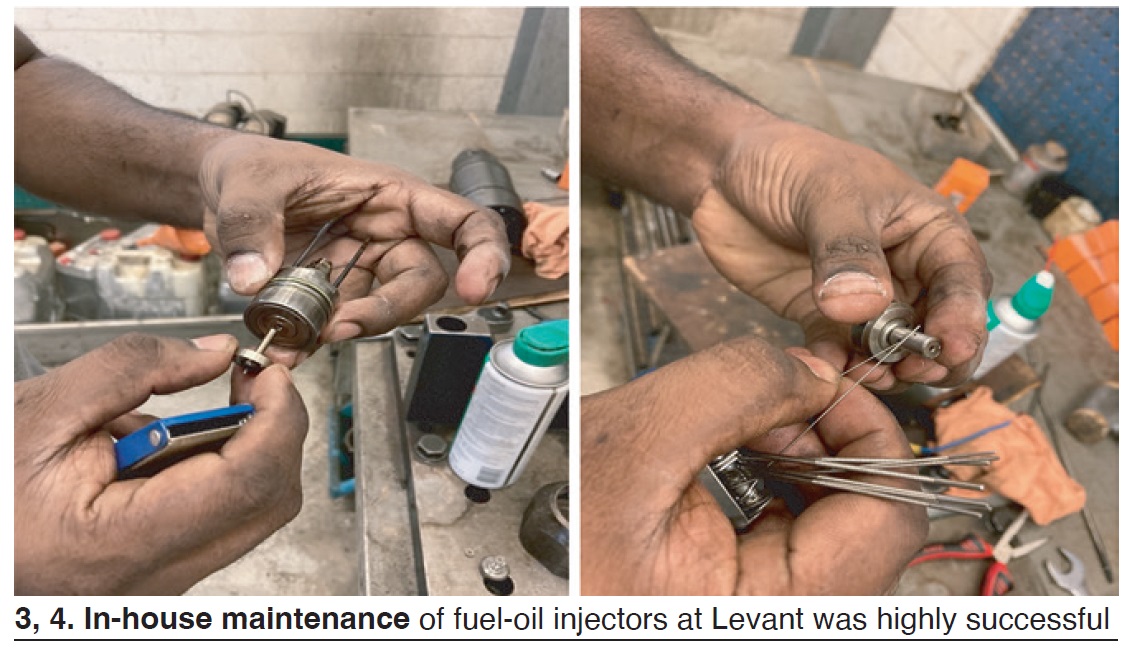

Challenge. Fuel-oil injectors on Levant’s recip engines were failure-prone. There were several reasons for the poor performance, but the problem facing plant personnel was the absence of service instructions from the manufacturer. Undaunted, staff set about developing a project to reduce maintenance and shipping costs.

Solution. Several steps were involved: Dismantle the injectors with special tools designed and fabricated in-house, cleaning and servicing the solenoid with a special cleaner (Figs 3 and 4), bench testing the injectors more than 20 times, and verifying injector performance in the engine.

Results. All objectives were met: (1) Performance of serviced injectors was as good as that achieved with new injectors. (2) Maintenance saving in 2022 attributed to servicing injectors using plant personnel was about $170,000.

Project participants:

Dhanapalan Thangadurai

Ahmad Bani Hani

Abdullah Dabaybeh