By some counts, says James E Timperley of J E Timperley Consulting LLC, over 300,000 electronic medical devices—such a pacemakers, defibrillators, cochlear, and neurostimulators—are implanted in Americans annually. Millions of these appliances are in service, covering all age groups in today’s population. This means that perhaps 1% of all people entering a powerplant may have some kind of electronic medical device. Providing a safe working environment for these individuals is more important than ever.

Electrical interference can pose a serious problem: It can disable any of these electronic devices. This danger can be from high-voltage electric fields, as in a switchyard, or high magnetic fields near large generators, bus systems, and/or transformers. Plant personnel normally are protected against dangerously high voltages by secure fences or metal structures.

However, high magnetic fields are another matter. Signage warning to maintain a safe distance when a microwave oven is operating has been standard for decades. Similar signage is needed for protection of people working in generating stations—including staff, contractors, and visitors. But this is an often-overlooked precaution where high 60-Hz magnetic fields are present. Such signage could be similar to the high sound-level warnings in locations where double hearing protection is required.

There are several suppliers of medical appliances. The inherent sensitivity of these devices to high electric or magnetic fields varies widely, and how a doctor programs a specific device also influences it sensitivity to outside influences. Only a physician and the device manufacturer can provide specific guidance for maximum field safety limits for each appliance.

An internet search for work-related safety protocols provides little useful information about the industrial work environment. Online information discusses warnings about exposure for a variety of commercial products—such as metal detectors, cell phones, 2-way radios, portable generators, arc welding equipment, gasoline ignition systems, electric fences, and medical procedures. There is almost no information available on the strong power-frequency electric or magnetic fields present in powerplants.

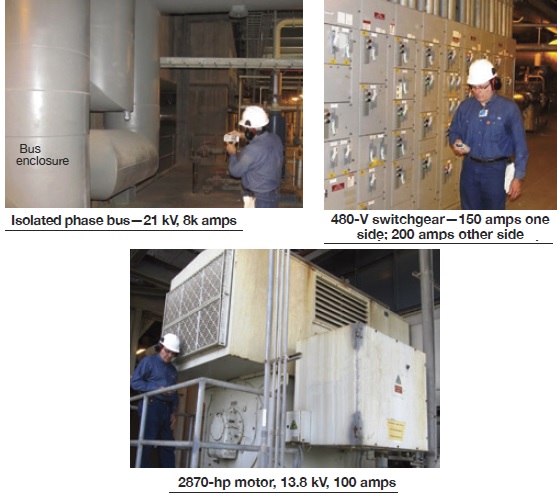

Most modern generating stations have meal-clad electrical equipment. This greatly reduces external electric (E) fields. The magnetic (B or H) field also is reduced by the metal, but penetration of these enclosures by high magnetic fields still can be a problem. Electric current of 5000 amps or higher usually poses a risk, and most powerplants will have current of this magnitude on the main bus, the auxiliary bus, near the transformers, and/or near the switchgear. All these locations easily can have extremely high gauss readings.

Measurement of magnetic fields must be conducted in the specific plant and plant environment where a worker or visitor may be exposed (photos). Contractors are available to conduct such surveys, but they must be accompanied by plant staff with an understanding of the equipment. The load when readings are collected must be recorded. Preferably, the survey will be taken at or near maximum load. In general, a high reading is considered to be 1 gauss or more.

In sum, a magnetic-field survey of a plant is not difficult to perform. With accurate measurements, and proper interpretation, areas of high magnetic fields can be determined. These areas then can be properly posted with appropriate signage.

In order for everyone onsite to be properly informed, it is strongly recommended that the high electric and magnetic fields, and the posted signage, be a topic included in the safety meetings conducted for all plant visitors. These precautions may prevent a serious medical emergency to personnel served by any of these medical devices.